Iron-Carbon System Phase Diagram

Iron & carbon make a series of alloys that include a number of steels & cast iron. Steels are the alloys which contain up to 1.2% of carbon whereas cast irons contain carbon within range of 2.3% to 4.2%. Alloys with carbon greater than 4.6% have poor properties and therefore not utilized.

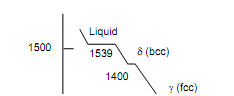

The carbon atom is smaller than the iron atom (the diameters being 1.54 A & 2.56 A respectively) and dissolves interstitially in iron. Pure molten iron solidifies at temperature 1539oC in bcc structure. At temperature 1400oC, on further cooling this structure modify into fcc and again at 910oC back to bcc. In reverse order (that means form room temperature) these three structures are named as α, γ and δ.

The α-iron is ferromagnetic however loses its ferromagnetism while heated above 770oC (curic temperature). The non-magnetic α-iron was previous known as β-iron till X-ray studies illustrated that structures of α − & δ − irons are similar. The γ-iron is the structure of closest packing while α − & β − irons are not. There shall be abrupt changes of dimensions at transitions α to γ & γ − β. Figure 7 depicts the cooling curve of pure iron.

Figure: Cooling Curve of Pure Iron with Steady Rate of Heat Loss

Alloys in iron-carbon systems also undergo complex structural changes which play an important role in deciding their characteristics. Changes that take place in iron-carbon system are illustrated in iron-carbon phase diagram of Figure 8. Strictly speaking the diagram refers to the iron-iron carbide system but still the phase relationship can be expressed in terms of carbon percentage, therefore the name.

Iron-carbon diagram is divided in various phase fields characterised by the existence of one or mixture of two phases. The liquids above that only molten metal in liquid state might exist are identified as ABCD. Iron & dissolved carbon exist in the liquid state. The solidus below which iron-carbon exist in solid state is identified as AEPGCH. Between these two lies there exist mixtures of solid and liquid. α and γ phases can dissolve carbon and the solubility changes with temperatures. The solid solution of carbon in α-iron is called ferrite while the solid solution of C in γ-iron is known as austenite. Ferrite and austenite are also designated as α and γ respectively. the solubility of C in austenite is upto 0.2% while ferrite can dissolve C only upto 0.025%. The C solubility in austenite changes along GK in austenite and along LN in ferrite. Beyond point C on solidus, the compound Fe3C which is cementite, separates. Cementite is hard and brittle whereas ferrite on the extreme left of phase diagram is soft and ductile. Austenite also transforms into cementite along the ling GK and into ferrite along IK.

The line IK and GK are respectively designated as A3 and Acm. Austenite is unstable below the lines A3 and Acm if carbon content is less than 0.8%. Austenite begins to transform into ferrite on cooling and gets enriched in carbon along line A3 until point K is reached. Similarly for carbon content between 0.8 and 2.0% iron carbide will precipitate and carbon in austenite will vary until point K (carbon 0.8%) is reached. At point K austenite will transform into pearlite. Pearlilte refer to an intimate mixture of ferrite and cementite (Fe3C) along characteristics lamellar structures composed of alternate platelets of ferrite and cementite. The transformation reaction at K in which a single solid phase splits into two phases is termed eutectoid. The equation is written as following

Solid phase (A) ---> Solid phase (B) + Solid phase (C)

(Austenite) (Ferrite) (Cementite)

Apparently at point K three phases exist (P = 3) and three are two components (C = 2), hence using Gibb’s phase rule the degree of freedom, F can be calculated.

Gibb’s rule at constant pressure,

P + F = C + 1

F = 2 – 3 + 1 = 0

Therefore the eutectoid point like eutectoid point is non-variant.

Slightly above 110oC at point C on solidus, the eutectoid transformation takes place. The liquid state at C contains 4.3% C and this liquid begins to transform into two solid phase. One phase is called Ledeburite which is eutectic mixture of austenite and cementite while the other phase is cementite. On additional cooling eutectic austenite transforms slowly into cementite, varying composition along GK till it changes into pearlite and cementite at eutectoid point K.