Heat Treatment Of Steel

A range of properties may be produced in steels because the structure of various phases of microstructure depend upon the rate of cooling. Some aspects in this connection have already been explained. In this section specific treatments shall be outlined. All heat treatment processes consist of three main steps.

(1) The heating of metal to preset heat treating temperature.

(2) The soaking of the metal at temperature till the structure becomes uniform throughout the section.

(3) The cooling of metal at some of pre-determined rate such like well cause the formation of desirable structure.

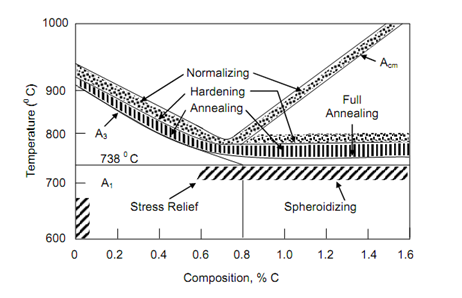

The heat treatments are normally applied to hypo-eutectoid carbon steels. These are: annealing, normalising and hardening. The temperature to that heating is done in all three cases is about 50oC above A3 temperature as indicated in Figure.

Figure: Heat Treatment Range for Carbon Steels

The heat treatment of other steels shall be discussed in specific section where these steels are described.