Hardenability Of Steel

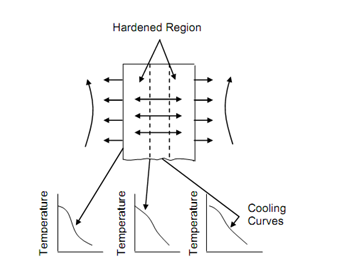

While a piece of metal is quenched its loss of heat is calculated by several factors but ore face can be easily understood that the loss shall not be uniform from total volume. That part of the metal that is in direct contact with quenching media shall lost heat faster than the inner side. This shall bring thickness or diameter of the part into focus to play vital role in hardening. Figure 24 shows the cooling curves for surface, for material just below the surface and the core. The cooling rate inside the material is governed by thermal conductivity of the steel. This is also the function of the thermal gradient existing in the piece to be hardened. There is always a possibility that at the inner core the rate of cooling is less than the critical rate resulting into unhardened material there.

Figure: Depth of Hardening in Steel

The depth of hardened layer is the measure of hardenability. A good hardenability shall mean even thicker sections are uniformly hardened. Alternatively a poor hardenability shall produce a soft core inside the piece of steel. The hardenability is based upon following factors :

(a) The steel composition plays vital role. The steels with high carbon content harden to a greater depth than steels along lower carbon for the former have lower critical cooling rate. Alloying element such like chromium develop the hardenability.

(b) The quenching medium.

(c) The section dimensions.

The standards explained the steel hardenability by stating the ruling section which is maximum thickness which may be utilized and still achieve the stated properties throughout the section. Size of thickness also plays vital role in terms of distortion that might occur in the material. Variations in the rate of cooling within the component may lead to different amount of contraction at different points across the section. This differential contraction shall result into the distortion of the component.