Cutting Conditions:

Fc = C1 (σt )α ------------ (5)

Fc = C2 (BHN)β -------------- (6)

Here, C1, C2, α and β are constants based upon workpiece material properties and cutting conditions both. BHN refer to Brinnel hardness number and σt refer to tensile strength of workpiece material.

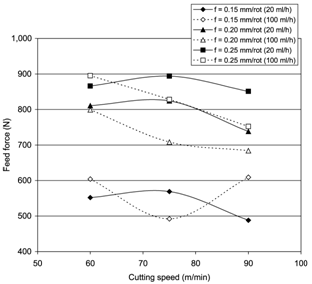

Through increasing depth of feed rate (f) or cut (d) or both, the cross-sectional area of the uncut chip & the volume of the deformed material shall increase, and therefore, the resistance (or forces needed) for the chip formation shall also enhance (Figures 6(a) and (b)). A enhances in the depth of cut enhances the width of uncut chip, and it enhance the forces acting upon the tool rake face and flank face both. This is found that there is a kind of linear relationship (Figure 6 (a)) as follows:

Fc = C3 d -------------- (7)

A enhance in feed rate (or uncut chip thickness) also enhance the cross-sectional area of the uncut chip however this relationship is not linear (Figure 6(b)). This is expressed as

Here, δ < 1 if f > 0.1.

Fc = C4 f δ ---------------------(8)

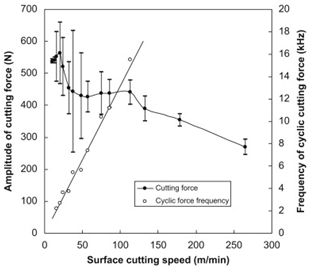

Influence of cutting speed on the cutting force is illustrated in Figure 6(c). When turning at cutting speed is greater than 50 m/min, the force & cutting speed follow the kind of relationship as illustrated in Figure 6(c) on and above 400 m/min where the cutting procedure stabilizes, and after that Fc remains practically constant.

(a)

(b)

(c)

Figure: Effect of Various Parameters on Cutting Force (a) Depth of Cut, (b) Feed Rate, (c) Cutting Speed

Althrough, the relationship among cutting force and speed for brittle materials is several from what is illustrated in Figure(c). This relationship might be expressed like an equation given below

Fc = C5 Vc -n (for 50 ≤ Vc ≤ 500 m/min) . ------------- (9)

Here, C5 refer a constant coefficient and n refer an exponent which based on the workpiece material and cutting conditions.