Physical Effects of Radiation

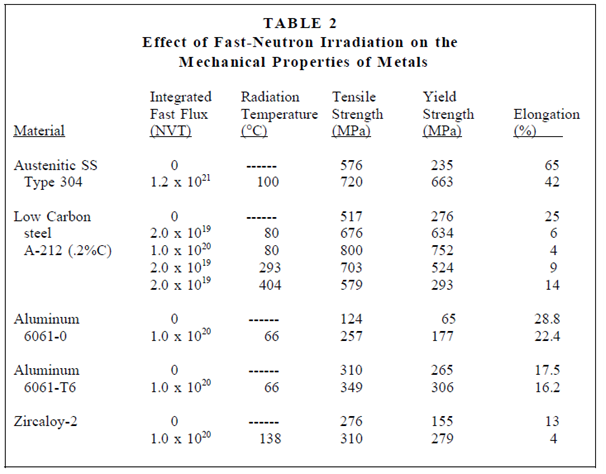

The common physical and mechanical effects of the irradiation of metals through fast neutrons and other high-energy particles are described in below table.

For fast neutrons, the changes are commonly undetectable below contain radiation levels (fluences below 1022 neutrons/m2). Along with increasing radiation levels, the magnitude of the effects increases and might reach a limit at extremely large fluences. The effects listed in Table are commonly less important at elevated temperatures for a provided fluence and a few defects could be removed through heating (annealing).

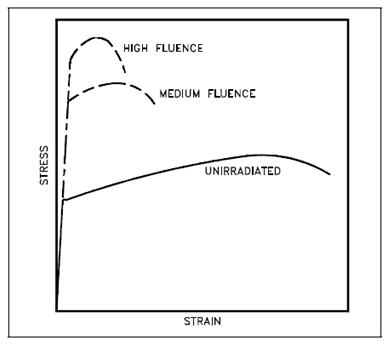

The yield strength and the tensile strength both of a metal are raised through irradiation, as displayed table, but the increase in yield strength is commonly greater than the increase in tensile strength.At the similar time, ductility is decreased through irradiation as shown in below figure that is representative of the behavior of several metals, involving steel and zircaloy. The accelerated decrease in the ductility of reactor vessels is due to the phosphorous (P), residual copper (Cu), and nickel (Ni) content in the vessel steel.

Figure: Qualitative Representation of Neutron Irradiation Effect on Many Metals

To stainless steel exposed to a thermal reactor fluence of 1021 neutrons/cm2, the tensile properties display a few increase in ultimate strength (tensile strength), an almost threefold gain in the yield strength, and a drop of about one third within ductility (elongation), as display in another table.

The NDT (Nil-Ductility Transition) temperature that is the temperature, at that a given metal modifies from ductile to brittle fracture, is frequent markedly increased through neutron irradiation. An increase in the NDT temperature is one of the most significant effects of irradiation from the standpoint of nuclear power system design. For economic purpose, the huge core pressure vessels of huge power reactors have been constructed of low carbon steels.

The loss of ductility and rise in the NDT temperature of these vessels is a main concern to reactor designers since of the increased chance of brittle fracture.Brittle fracture of a material is a failure occurring through crystal cleavage and accompanied through fundamentally no yielding. A brittle fracture of a pressure vessel resembles the shattering of glass.Because such a failure would be disastrous, it is essential to known the brittle fracture mechanism. In During normal reactor operation, the pressure-vessel steel is subject to increasing fluence of fast neutrons and, conclude, the NDT temperature increases steadily.The NDT temperature is not likely to rise suitably to approach the temperature of the steel in the pressure vessel. Therefore, as the reactor is being cooled down, the temperature of the vessel might drop below the NDT value when the reactor vessel is still pressurized. Brittle fracture may then occur.

One of the areas of the reactor vessel which is of most concern is the beltline region. A Nuclear Regulatory Commission needs which a reactor vessel material surveillance program be conducted (in accordance along with ASTM standards) in water-cooled power reactors.A Specimens of steel used inside the pressure vessel must be placed within the vessel situated near the inside vessel wall in the beltline region, so in which the neutron flux received through the specimens around in which received through the vessel inner surface and then the thermal environment is as close as possible to which of the vessel inner surface.A specimen is withdrawn at prescribed intervals in during the reactor lifetime and is subjected to impact tests to determine new NDT temperatures. Below figure displays the increase in NDT temperature for a representative group of low carbon steel alloys irradiated at temperatures below 232ºC. Several current reactors have core pressure vessel wall temperatures in the range of 200ºC to 290ºC, so in which an increase in NDT is of extremely real concern.

Irradiation frequently reduces the density of a metal over a certain temperature range, so in which a specimen exhibits a rise in volume or swelling. A swelling of stainless steel structural elements and fuel rod cladding, conclusion from fast neutron irradiation at the temperatures existing in fast reactors, is a matter of great concern in fast reactors.The swelling could cause changes in the dimensions of the coolant channels and also interfere along with the free movement of control elements.