Slide ways and Linear Motion Systems

Slide ways

Another important element for consideration during the design of the CNC machine tool is the slide motion. The conventional slide ways such like the flat, V, round or dovetail have large amount of friction because of the sliding contact between the sliding members. It will not allow for faster slide movement demanded by most of the CNC machine tools. Therefore in CNC machine tools, rolling friction elements capable of providing an extremely low friction are utilized which are generally termed as linear motion or LM devices.

Linear Motion Systems

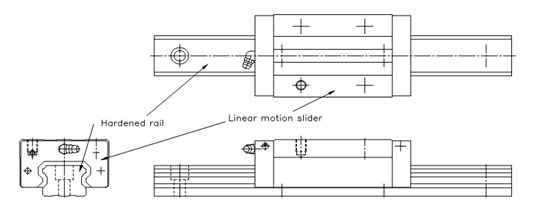

A typical linear motion guide utilized in CNC machine tools with hardened rails is illustrated in Figure 4. These have a number of recirculating balls that provide a rolling motion among the slider and the rail. These balls shall be circulating through the rolling tracks by providing an extremely high rigidity and low friction for the movement of the axes. With a slide way with LM device this will be possible to move the slides with a very light push. It would drop the wear rate allowing the systems to maintain the accuracy during its life.

Figure 4 : Antifriction Guideways Used in CNC Machine Tools

Another type of linear motion device is the utilization of a ball bush where the balls are arranged in a track inside of a bush that can slide along a ground rod to give the linear motion similar to a round slideway utilized in conventional machine tools.

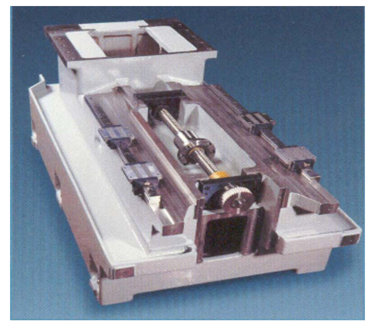

A typical machine bed is illustrated in Figure 5 using the recirculating ball lead screw along with LM guides for providing an extremely fast feed motion.

Figure 5 : Use of Recirculating Ball Screw and the LM Device for Axis Movement in the Bed of a CNC Machine Tool