Typical Installations of DNC

As discussed earlier, the serial communication port available in the personal computer is generally used for linking the CNC machine tool for DNC function. All the modern machine tools are provided with a serial port or RS 232C port so that it can be directly connected as shown in Figure 8.

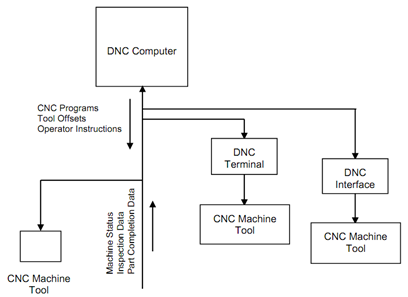

Older NC and CNC controllers that have little or no internal memory or communications capability are difficult to be integrated into a DNC system. Such controllers then have to be provided with a special interface unit, which normally can be plugged into the tape reader port available in such controllers. Such systems sometimes are called the Behind the tape reader or BTR systems. Once the system is installed, even these older NC controls can get integrated into a network as shown in Figure 10. They can then run long part programs that would have required miles of paper tape. All other part program management, editing and other functions found only on newer CNC controls are all can be done either on the interface terminal or on the DNC terminal.

The use of DNC involves additional cost in terms of the network, computer, terminals and the software. Therefore, it is necessary to see when DNC will be useful. The use of DNC can be justified under the following conditions :

- When the interconnected CNC machines are large in number. With smaller number of machine tools, it is easier to handle the machines directly unless the drip feeding becomes necessary such as in tool rooms.

- When the part program sizes are very large and cannot be held in the part program memory of the MCU.

- Part program variety is large and batch sizes are small. In such cases, the machine tools need to be fed by a large number of part programs in a day which can easily justify the use of DNC.

- Very frequent changes in program designs, that require more time for the programmer to spend at the part programming terminal which is easier than the MCU.

Figure 10 : Typical Direct Numerical Control Operation with Separate Terminal for each Machine Tool

It is generally expected that there will be a 2 to 5% increase in the operational efficiency of the CNC machine tools with the use of DNC. If the typical cost of a DNC installation is about Rs 500,000 for a 10 machine configuration, then it is possible to recover the cost of the installation in less than a year's time assuming a machine hourly rate of Rs 300 with a 2-shift operation.