Cell Control in DNC

As mentioned earlier, DNC provides for better utilisation of the CNC machine tools by providing the part programs as and when required. However, the running of the CNC machine tool does not depend upon the part programs alone. It also requires the necessary tools to run the particular part program as well as the blank workpieces in position for running the said programs. The choice therefore falls on the ability of the DNC computer to maintain the interaction with other facilities within the shop such as the work preparation area as well as the tool crib.

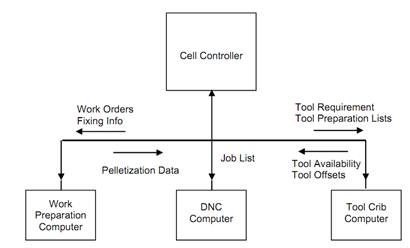

It is therefore possible to visualise a better DNC model, which we may call as the Cell Controller is schematically shown in Figure 11.

In this scenario, it is possible to visualise a separate terminal at each of the important areas, viz. the work preparation area and the tool preparation area shown as tool crib in Figure 11. At each of these terminals, the operators will be able to input the data necessary for integrating into the system.

The cell controller will send the following information to the work preparation area :

- Work orders, the part numbers of the planned jobs with quantity.

- Fixturing information that gives the details of fixtures used as well as instructions for fixturing.

- Palletization data in terms of the pallet numbers to be used for the individual parts along with the pallet offsets if any.

Figure 11 : Enhanced Direct Numerical Control Operation Linking the Tool and Work Preparation Areas with CNC Machine Tools

Work preparation area completes the preparation of the blank workpieces and clamps the workpieces on the pallets or work holding fixtures, and then transports them to the respective destination with information back to the cell controller.

Similarly, the cell controller will send the following information to the tool crib :

- Tool requirements in terms of the actual tools that are required for the jobs that are scheduled for the day.

- The tool setting up instructions in terms of the type of adopter, tool holding method to be used, etc.

The tool crib may come back to the cell controller with information on the availability of the tools, the tools that are assembled, the tool offsets and the tool lives which could be used for the tool life management.

Thus the cell controller will be coordinating the activities of all the three components of the total manufacturing system concerned thereby improving the productivity of the total system. At the upper end, it is possible to have the cell controller linked to the factory production control system to provide the necessary feedback.