Degree of Polymerisation:

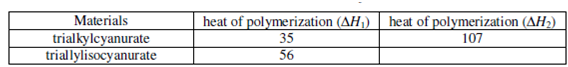

The area observed in DTA curve is directly related to heat of polymerization and can be expressed in terms of per mole or per g. Assume the DTA graph of polymerization process of trialkylcyanurate and triallylisocyanurate. Samples were prepared by mixing two elements Al2O3, one part monomer 0.1 part catalyst as a 50 % paste in tricresyl phosphate and heating the mixture at a rate of 8 0C per minute. Typical values of heat of polymerization as estimated from the peak area are given in Table.

Table : Estimated Heat of Polymerization

Further the area (size) of peak appears in DTA curve had a great value in assessing the degree of curing. This is completed through the residual cure remaining in a polymer system after various treatments. That approach has been applied for estimation of degree of curing in an unsaturated polyester-styrene copolymer cured at ambient temperature. The variation in the size of the curve represents the percentage of curing in 2 hours 63 % , 3 hours 68.6 % 4 hours 74.3% , 5 hours 77.0 % and 6 hours 78.2%. Similarly the relative change in the heat of reaction measured by DTA also gives information regarding role of catalyst and degree of crystallinity and decomposition of polymer samples.