Plastic Deformation Around Crack Tip

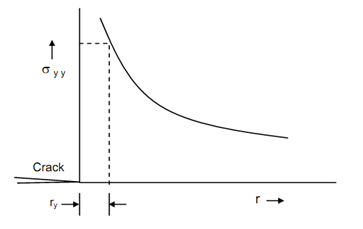

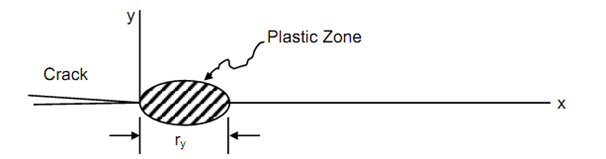

Both Griffith's and Irwin criteria of fracture are applicable to materials that are brittle and have high yield strength. Attention is invited to Eq. (1) and Figure to note that the stress tends to be infinite as crack tip is approached. For r = 0, the stresses are infinite at crack tip. It, however, can be released that no real material can bear infinite stress at any point and hence this mathematical tendency to infinity cannot exist in any real material. What actually happens is that the material in close vicinity of crack deforms plastically as soon as the stress becomes equal to yield strength. Thus in all engineering materials a crack tip is always surrounded by plastically deformed zone of small size. The size of the plastic zone may be calculated at best in one situation when material is regarded as non- strain hardening (a non-strain hardening material will deform plastically at constant stress equal to yield strength). Therefore, the stress in crack tip plastic zone will not exceed the yield strength. In Figure (a), a stresssY = yield strength, is marked on syy axis. The abscissa of point of intersection of horizontal line at syy =sy with syy - r curve is the distance rY which is the plastic zone ahead of crack tip in the line of crack. Figure (b) shows the plastically deformed zone surrounding crack tip.

(A)

Figure: Plastic Deformation in the Region of Crack Tip

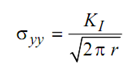

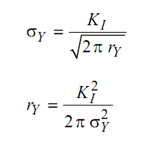

From second of Eq. (1), in the line of crack, i.e. for q = 0.

whensyy assumes value of sY r assumes value of rY. Therefore,

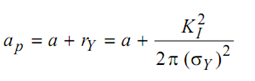

For all practical purposes, rY is regarded as crack length extension. Thus, the modified crack length will be

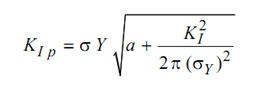

This will modify the stress intensity factor also. This modified KI is