Fracture Under Uniaxial Loading

In previous Section of Mechanical Properties and their Determination this example was briefly considered. Two types of fracture, viz. ductile with cup and cone and brittle fracture with granular appearance were identified. The components of stresses instigating these fractures were also identified.

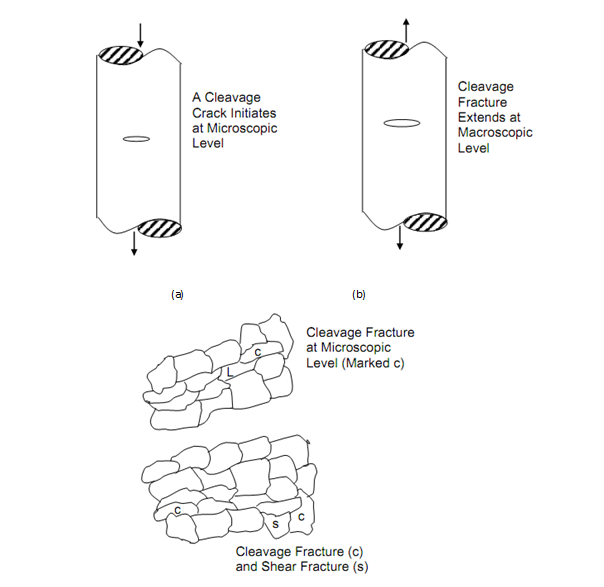

The cleavage fracture beginning from any region of high stress concentration, under uniaxial tensile loading will travel perpendicular to the tensile axis. The profile of fracture plane of cleavage fracture will appear flat or square to the axis. All crystalline materials have preferred cleavage planes in each grain or crystal. Most metallic materials are crystalline and in their grains the cleavage planes may not be aligned perpendicularly to tensile axis. This will cause fracture plane to change direction as shown in Figure. However, such change of direction will be confined only at microscopic level and at macro level the surface will appear flat.

Like cleavage planes, the crystals also have shear planes on which shear fracture can occur. In two adjacent crystals the orientation of cleavage and shear planes may be such that one permits cleavage whereas other supports shear and hence the crack at microscopic level may have a mixed mode. The gross appearance of fracture surface will be governed by predominant microcracking. For example, in case of mild steel when a flat fracture is obtained at macroscopic level (in impact specimen) some grains do fail by shear.

(c)

Figure: Extension of Cleavage Fracture

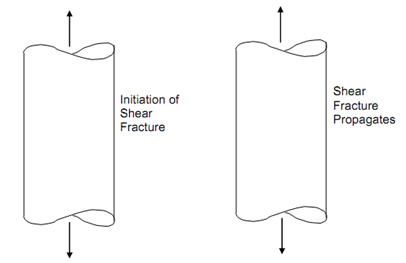

Extremely localised plastic deformation causes shear fracture. Slip planes on which slip or sliding can take place exist in crystals or grains of all crystalline materials like many b.c.c. metals and all f.c.c. metals. A slant fracture results when slip is confined to only one set of parallel planes. Such fractures often occur in single crystals along planes at 45o to tensile stress. Single crystals of h.c.p. metals are the example. Polycrystalline metals of very ductile nature like gold and silver may eventually be drawn down to a point before rupture occurs. Figure (c) shows slant fracture and Figure (d) shows rupture ending in a point.

At microscopic level the fracture propagate along 45o to tensile stress as shown in Figure.

(a) (b)

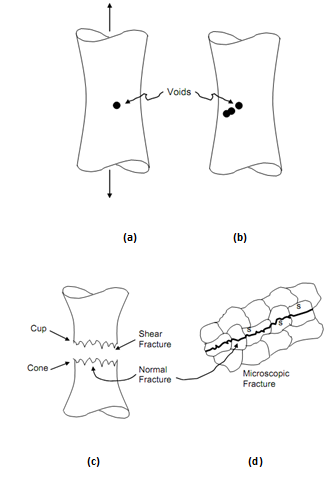

In polycrystalline material the advancing shear crack follows the path of maximum shear stress. However, it may be pointed out that this path depends upon orientation of slip plane and slip direction in a grain. Voids are formed at different points at inclusion, mainly non-metallic. With increasing deformation these voids coalesce to extend crack. The formation of voids in round specimen take place in the centre because enough plastic deformation has already taken place due to shear stress and resulted in necking of specimen (reduction of diameter in localised region of specimen). The coalescence of voids or macroscopic fracture path is perpendicular to tensile stress in tension specimen. On the microscopic scale the fracture is quite jagged as the crack advances by shear mechanism. This fracture is often termed fibrous because of appearance. The final fracture in ductile materials like low carbon steels takes place fast due to shear stress along 45o plane. This fracture is not jagged but smooth and wholly due to shear. The combined appearances of the fracture is cup and cone (already shown in Figure of Unit “Mechanical Properties and their Determination”).