Fracture Toughness

Fracture toughness which is the critical SIF of crack, becomes in important mechanical property. This property controls the propagation of crack. To guarantee that the crack does not propagate one would keep the gross stress, s and crack length, a, in control so that at any instant stress intensity factor < fracture toughness of the material. For Mode I, the above statement can also be written as

KI < K IC --------------(i)

One can determine KI or SIF of a crack in a finite body by using any one of experimental techniques (compliance calibration or photoelasticity) or numerical methods (boundary collocation or finite element). The quantity has already been expressed as

KI = σY√ a ---------------(ii)

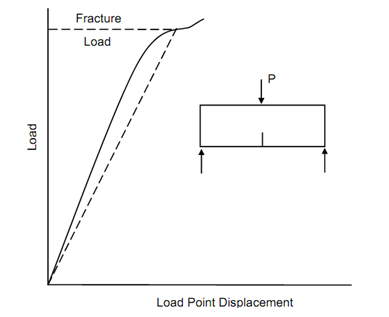

Thus to achieve the objective in (i), it is KIC or fracture toughness of the material that has to be determined. Simple experiments can be performed to determine KIC. Standard specimens of cracked plate or cracked beam can be used in these experiments. The specimen of known dimensions and initial crack length is gradually loaded till the specimen fractures. This load is plotted (on the plotter) against load point displacement which is related to crack length. This relationship helps establish the crack length corresponding to load that causes fracture. Alternatively the crack length can be measured from fracture surface. The appearance of fracture surface over which crack travels fast during fracture is different than that part of surface over which crack grew stably. The value of crack length, (say ac) along with the fracture stress (calculated by using fracture load) and non-dimensional SIF corresponding to ac (say Yc) are substituted in (ii) to calculate KIC, i.e.

--------------- (16)

--------------- (16)

A typical Load-Displacement curve is shown in Figure

Figure: Typical Load-Displacement Curve in a Fracture of a Pre-cracked Specimen

Determination of fracture load from a curve like one in Figure depends upon several factors which are not discussed right now. A test specimen will be required to have certain minimum thickness and initial crack length. These are two important factors to obtain a valid Load-Displacement diagram. ASTM has standardised the specimens for valid fracture toughness. In such specimens, the fracture occurs without plastic deformation in the region of crack tip and crack faces also remain undeformed. The crack length at the fracture can be measured from the two parts of the specimen that separate along the precrack.