Effect Of Plastic Deformation On Fatigue Crack Growth Rate

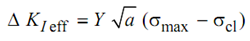

Because of plastic deformation the crack may close at a stress level scl which may be higher than smin. This will effectively reduce the magnitude of ΔKI. Effective value of the differential stress intensity factor may be written as

Δ K I eff = K I max - K I cl

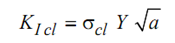

where, KI cl corresponds to scl in the sense that

and hence

This effect has been investigated experimentally for the regime of σmin > 0 and the experimental results suggest that

Δ K I eff / ΔK I = 0.5+ 0.4 R

where, R is the ratio smin /smax. Apparently if Eq. (30) is extended to pulsating stress cycle withsmin = 0, Δ K I eff will be only half of Δ K I , indicating that fatigue crack growth rate is reduced in fluctuating and pulsating stress cycle. This conclusion was also drawn from crack growth model in previous section.