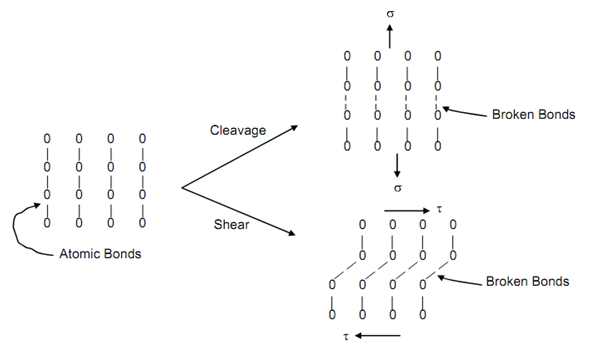

Cleavage And Shear Fracture At Atomistic Level

So far we have been referring to fracture or crack instability at macro level where crack lengths start from size of 1 mm .At atomistic level fracture occurs over regions whose dimensions are quarter of a micron (1 micron is 10– 6 m and is expressed as µm). Fracture occurs at microscopic level over regions whose dimensions are of the order slightly in excess of hundredth of a mm.

At atomic level fracture occurs when bonds between them break across fracture plane and new surfaces are created. This can happen by breaking of bond perpendicular to plane of fracture or by shearing of bonds across the fracture plane as shown in Figure. The former is known as cleavage while latter is known as shear. The cleavage occurs when local stress at atomistic level becomes equal to theoretical cohesive strength which is ~ E/10. The theoretical shear strength is G /10 and local shearing stress must assume this value to cause shear fracture (G here is modulus of rigidity).

The fracture process at atomistic level requiring such high level essentially occurs at the tip of a macrocrack which was considered in previous sections. Such high stresses are existing because of high stress concentration due to such flaws as metallurgical inhomogencities or micro or macro cracks. Some specific types of fracture are now described.