Engine Lubrication:

An internal combustion engine would not run for even a few minutes if the moving elements were permitted to make metal-to-metal contact. A heat produced because of the tremendous amounts of friction would melt the metals and leading to the destruction of the engine. For avoid this, all moving categories ride on a thin film of oil which is pumped among all the moving elements of the engine.

Once among the moving elements, the oil serves two reasons. One reason is to lubricate the bearing surfaces. Another reason is to cool the bearings through absorbing the friction produced heat. The flow of oil to the moving elements is accomplished through the engine's internal lubricating system.

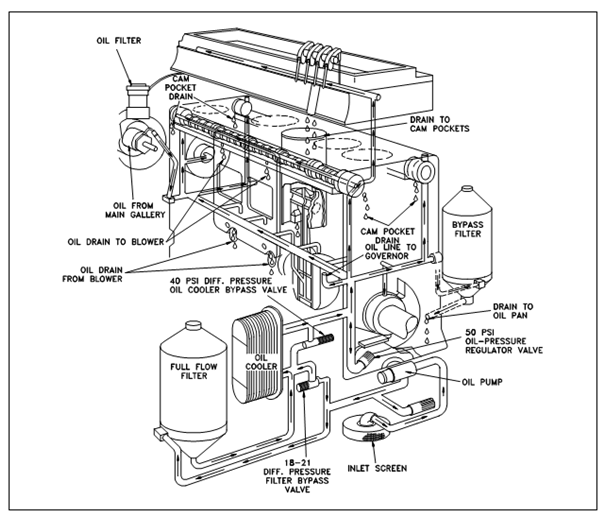

Figure: Diesel Engine Internal Lubrication System

Oil is stored and accumulated within the engine's oil pan where one or more oil pumps take suction and pump the oil by one or more oil filters as display in Figure. The filters clean the oil and erased any metal in which the oil has picked up because of wear. Cleaned oil then flows up into the engine's oil galleries. A pressure relief valve(s) manages oil pressure in the galleries and returns oil to the oil pan upon high pressure. An oil gallery distributes the oil to all the bearing surfaces within the engine.

At one the oil has lubricated and cooled the bearing surfaces, that flows out of the bearing and gravity-flows back within the oil pan. Inside medium to huge diesel engines, oil is also cooled before being distributed within the block. This is accomplished through either internal or external oil cooler. A lubrication system also supplies oil to the engine's governor that is elaborates later in this module.