Cylinder Heads and Valves:

A diesel engine's cylinder heads perform various functions. First one, they give the top seal for the cylinder bore or sleeve. Second one, they give the structure containing exhaust valves (and intake valves where applicable), the fuel injector, and essential linkages. A diesel engine's heads are manufactured in one of two ways. In one method, every cylinder has its own head casting that is bolted to the block. This method is used mainly on the larger diesel engines. In other method that is used on smaller engines the engine's head is cast as one piece (multi-cylinder head).

Diesel engines have two methods of admitting and exhausting gasses from the cylinder. They could use either ports or valves or a mixture of both. Ports are slots within the cylinder walls situated in the lower 1/3 of the bore. Look Figures for instances of intake ports, and note their relative location along with respect to the rest of the engine. While the piston travels below the level of the ports, a port are "opened" and fresh air or exhaust gasses are able to enter or leave, depending on the category of port.

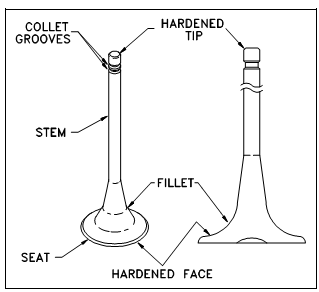

The ports are then "closed" while the piston travels back above the level of the ports. Valves are mechanically opened and closed to admit or exhaust the gasses as required. The valves are situated within the head casting of the engine. The point at that the valve seals against the head are known as the valve seat. Most medium-sized diesels have either intake ports or exhaust valves or intake and exhaust valves both.

Figure: Diesel Engine Valve