Identify Equipment Required and Compare it to What is Available

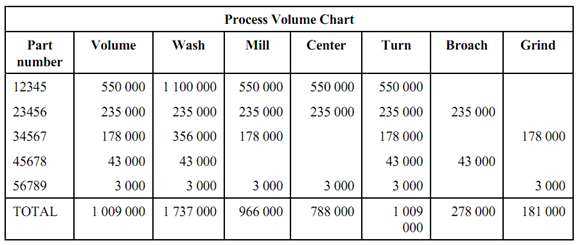

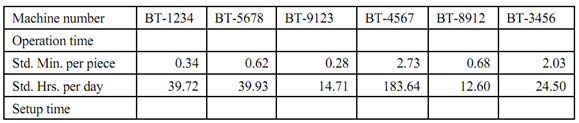

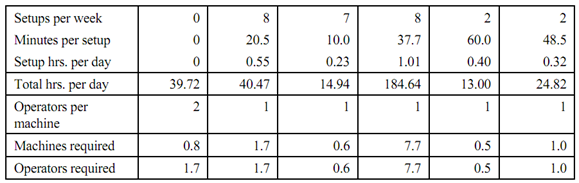

Once the developed process flow and the needed volumes are established, it shall be possible to produce the total capacity required. Sample process volume calculations are shown in Table 1. At this stage, it might be important to let the setup decrease as a means of getting the maximum advantage from the cellular operation. In these calculations, the utilization of all the resources, like as machine tools and the operators shall be shown depend on the average annual volumes taking into account the variability as described earlier. Therefore, this will show the resources that are over- or under-utilized in the new environment. Therefore, it may be possible at this stage to explore the possibility of adding up new equipment to relieve any of the possible bottlenecks or those contributing to the enhance in the throughput time in the cell. For instance, the wash station might be one such instance if it either a centralized facility or shared by a number of cells.

Table 1: Process Volume Chart

It might be good idea of keeping process volume chart in a spread sheet such like Excel to perform the what if analysis to balance the machine work load in addition to the operator workloads.