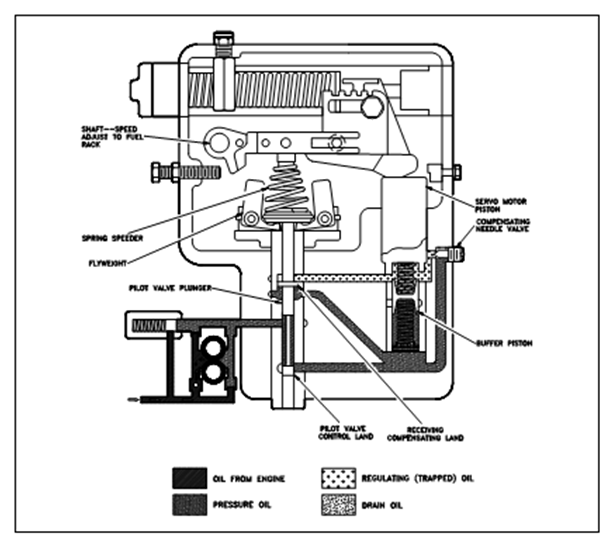

Cutaway of a Woodward Governor:

Under these conditions, equal oil pressures are maintained on both sides of the buffer piston and tension on the two buffer springs is equal. In addition, the oil pressure is equivalent on both sides of the receiving compensating land of the pilot valve plunger due to oil passing by the compensating needle valve. Therefore, the hydraulic system is in balance, and the engine speed remains stable.

While the engine load raise, the engine begins to slow down in speed. The decrement in engine speed will be sensed through the governor flyweights. The flyweights are forced inward (through the spring), therefore lowering the pilot valve plunger (again, because of the downward spring force). Oil under pressure will be admitted before the servo-motor piston (topside of the buffer piston) causing it to increases. That upward motion of the servo-motor piston will be transmitted by the terminal lever to the fuel racks, therefore raising the amount of fuel injected within the engine. The oil which forces the servo-motor piston upward also forces the buffer piston upward since the oil pressure on every side of the piston is unequal. That upward motion of the piston compresses the upper buffer spring and relieves a pressure on the lower buffer spring.

The oil cavities above and below the buffer piston are general to the receiving compensating land on the pilot valve plunger. Since the higher pressure is below the compensating land, the pilot valve plunger is forced upward, recentering the flyweights and causing the control land of the pilot valve to close off the regulating port. Therefore, the upward movement of the servo-motor piston stops while it has moved far sufficient to make the essential fuel correction.

Oil passing by the compensating needle valve slowly equalizes the pressures above and below the buffer piston, therefore permitting the buffer piston to return to the center position that in turn equalizes the pressure above and below the receiving compensating land. A pilot valve plunger then moves to its central position and the engine speed returns to its original setting since there is no longer any excessive outward force on the flyweights.

The action of the flyweights and the hydraulic feedback mechanism generates stable engine operation through allowing the governor to move instantaneously within response to the load change and to make the essential fuel adjustment to manage the initial engine speed.