Manholes

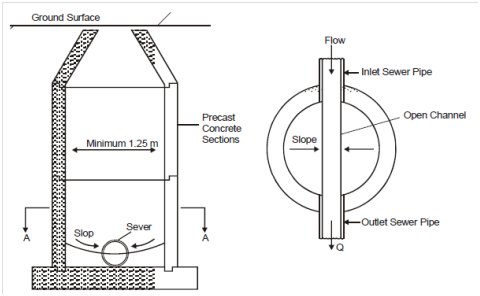

A manhole is an opening constructed on the alignment of a sewer to facilitate access into the sewer. A typical manhole for a lateral sewer is shown in Figure 4. Their principal purpose is to permit inspection (including sampling and flow measurement), cleaning, repair and removal of any obstructions. Manholes are located over the pipe centerline under the circumstances:

(a) When there is a change in the pipeline diameter,

(b) When there is a change in pipeline slope,

(c) When there is a change in pipeline direction,

(d) At all pipe intersections, and

(e) At the uppermost end of each lateral.

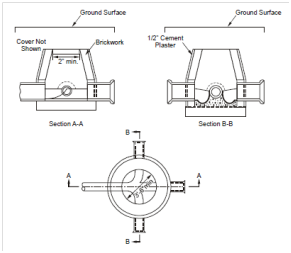

Figure 4: Sectional View of Lateral Sewer Manhole

On sewers, which are to be cleaned manually, which cannot be entered for cleaning or inspection, the maximum distance between the manholes should be 30 m. The spacing of manholes on large sewers above 900 mm diameter is governed by the following for the sewers to be cleaned manually.

(a) The distance upto which silt or other obstruction may have to be conveyed along the sewer to the nearest manhole for removal.

(b) The distance upto which materials for repairs may be conveyed through the sewer.

(c) Ventilation requirements for men working in the sewer.

For sewers, which are to be cleaned with mechanical devices, the spacing of manholes will depend upon the type of equipment to be used for the cleaning. The spacing of manholes above 90 to 150 m may be allowed on straight runs for sewers of diameters 900 to 1500 mm. Spacing of 150 to 200 m may be allowed on straight runs for sewers of 1.5 to 2.0 m diameter, which may be increased upto 300 m for sewers of over 2m diameter. A spacing allowance of 100 m per 1 m diameter of sewer is a general rule in case of very large sewers.

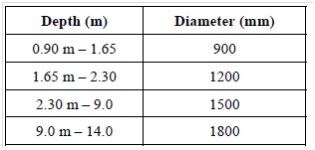

Manholes are directly constructed over the central line of the sewer. They are circular, rectangular or square in shape. Circular manholes are stronger and provide easier access as compared with other types of manholes and hence generally preferred. The inside dimension should be sufficient to perform the necessary operations regarding inspection and cleaning without difficulty. The inside diameter of circular manholes may be kept as given in Table 7 below.

Table 7 : Inside Diameter of Circular Manholes v/s Depth (CPHEEO, 1993)

Note: The dimensions of the manhole should not be less than internal diameter of the sewer + 150 mm benching on both sides (150 mm + 150 mm).

When the width of the sewer does not exceed the width of the manhole, the manhole is usually constructed directly over the centre line of the sewer. For better accessibility, the manhole, for very large sewers, may be centered over the sewer with a landing platform offset from an opening into the sewer itself. Consideration must be given to the need for the introduction of cleaning equipment into the sewer.

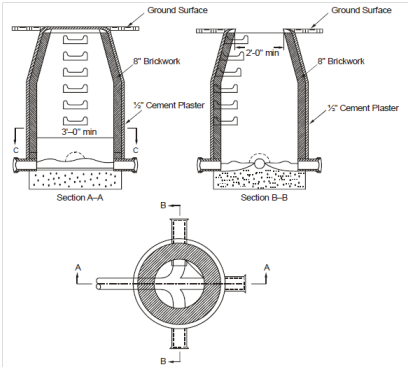

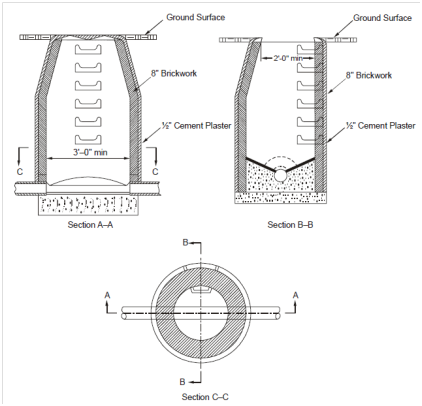

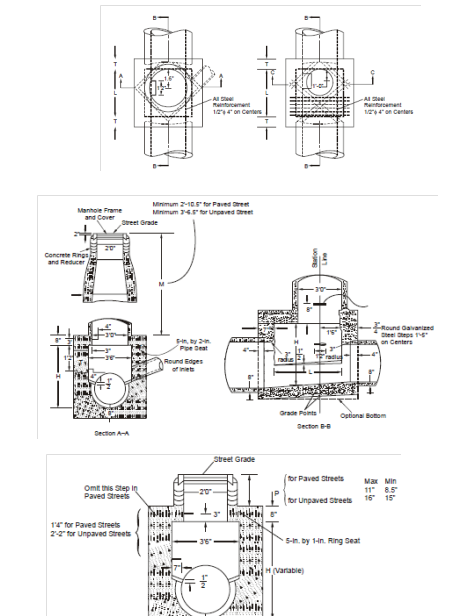

The opening into the manhole must enable a man to gain access to the interior without difficulty. Typical manholes of the types used by many municipalities are shown in Figures 5 to 8.

Figure 5: Typical Manholes

Figure 6: A typical Manholes with vertical side

Figure 7: A Shallow Manhole

Figure 8: A Concrete Pipe Manhole

A base slab of concrete preferably at least 150 mm thick should be provided on smaller sewers to support the walls of the manhole and to prevent the entrance of ground water. All sanitary flow should be carried in smoothly constructed V-shaped channels, which may be formed integrally with the concrete base or may be constructed separately of concrete or brick. The side height of the channel should be one-half to three fourths of the diameter of the sewer with the higher side height used where conservation of energy is important adjacent floor areas should be sloped to drain to the channel with a slope of 1 in 10. Where more than one sewer enters the manhole, the flowing-through channels should be curved smoothly and should have sufficient capacity to carry the maximum flow. Wherever the sewer changes direction or its size, or a branch sewer is allowed to join the system a manhole needs to be provided.

The materials commonly used for the construction of manhole walls include brick, poured concrete, precast rings and segmental block. The following influences the choice of the material:

(a) Cost in place, including material, labour and equipment.

(b) Durability under all reasonably expected conditions of service.

(c) Adaptability of the material to meet field conditions with particular reference to changes in location, grade or alignment made during construction.

(d) Depth of manhole and characteristics of surrounding material. The sidewalls of the manhole are usually constructed of cement brickwork 250 mm thick and corbelled suitably to accommodate the frame of the manhole cover. The brickwork should be plastered with cement mortar 1: 3 (1 cement : 3 coarse sand) and inside finished smooth with coat of neat cement. Where subsoil condition exists, a richer mix may be used and it shall further be waterproofed with addition of approved water proofing compound in a quantity as per manufacturer's specifications.

Manhole frames and covers are generally made of close-grained gray cast iron. All metal-bearing surfaces between the frame and cover, wherever subject to traffic, should be fabricated to insure good seating. Solid covers are preferable to the perforated type on sanitary sewers because they diminish the spread of objectionable odours and the entrance of surface waters. Adequate ventilation can usually be obtained through the house connections. Open-type covers are most common on storm and combined sewers. Locked or specially bolted-down covers may be used to prevent theft, vandalism or unauthorized entrance.