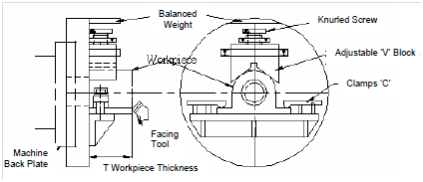

Turning Fixture

These are commonly special face plates. Their swing should be much lesser than the swing of the machine. These are used for quick location & clamping. Classical turning fixture is display in Figure face plate fixture. The workpiece rests on angle plate and its boss is centralized with machine axis through sliding v-block that can be operated with knurled screw. The overhang of turning fixtures should be minimum bare necessary for the operation. Fixture should be balanced with workpiece within position. The clamping arrangement should be capable of withstanding the several forces developed during operation.

1. Cutting force tangential to cutting circle.

2. Axial force and radial force because of feed of tool.

3. Bending forces because of pressure of tool on workpiece.

Figure: Turning Fixture (Boring and Facing Fixture)