Mixed-Bed Regeneration:

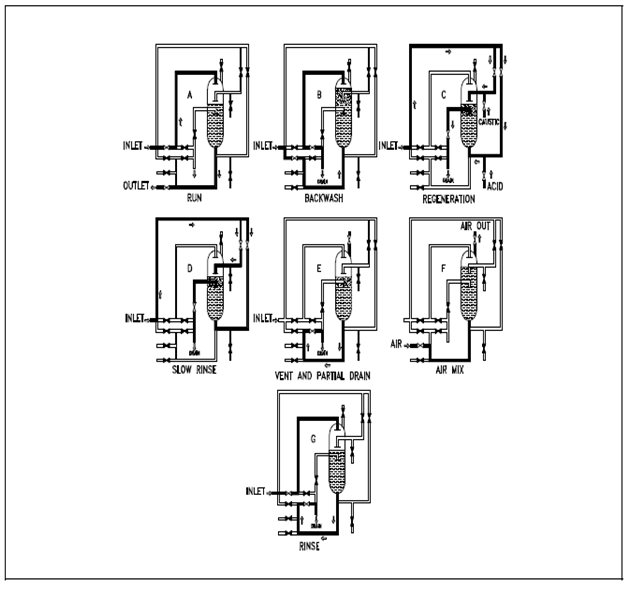

The mixed-bed demineralizer displays in Figure are designed to be reproduced in place, other than the process is more complicated than the reproduced of a single-bed ion exchanger. The steps in the regeneration are displays in Figure.

Below figure displays the mixed-bed ion exchanger in the operating, or on-line mode. Water enters by a distribution header at the top and exits by the line at the bottom of the vessel. Regeneration causes the effluent water to rise in electrical conductivity. A first regeneration step is backwash, as displays in below figure. Since in a single-bed unit, backwash water enters the vessel at the bottom and exits through the top to a drain. Further to washing out entrained particles, backwash water in a mixed-bed unit must also divide the resins inside cation and anion beds. An anion resin has a lower specific gravity than the cation resin; thus, as the water flows by the bed, the lighter anion resin beads float upward to the top. Therefore, the mixed-bed becomes a split bed. A separation line among the anion bed at the top and the cation bed at the bottom is called the resin interface. A few resins could be separated just while they are in the depleted state; another resin separate in either the depleted form or the reproduced form.

The original regeneration step is displays in Figure. Dilution water is mixed along with caustic solution and introduced at the top of the vessel, just above the anion bed. At the similar time, dilution water is mixed along with acid and introduced at the bottom of the vessel, below the cation bed. A flow rate of the caustic solution down to the resin interface is the similar as the flow rate of the acid solution up to the resin interface. Both solutions are erased at the interface and dumped to a drain.

Figure: Regeneration of a Mixed-Bed Demineralizer