Sheet Metalworking Processes

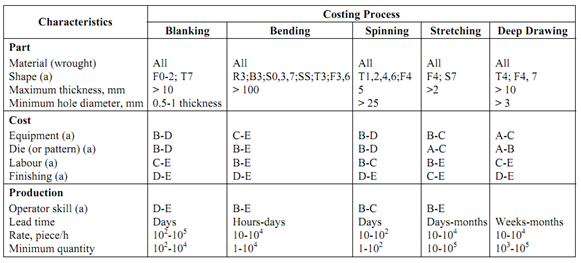

The starting material in these processes is flat-rolled product (hot-rolled plate, hot or cold-rolled sheet or strip); hence there are no limitations on width-to-thickness ratio : sheet metalworking is the process chosen for relatively thin products. Deformation is mostly by tension or tension compression, and limits are set by the formability of the material and only rarely by force or die pressure. Most processes are conducted cold; only heavy gage material is formed hot. Major process groups are shown in Figure 6, and characteristics of major processes are given in Table 3. Forming of wires, sections, and tubes is governed by the same rules as the forming of sheet; therefore, it is included here.

Table 3 : General Characteristics of Sheet Metal Working Processes Including Bar and Tube Bending