Bulk Deformation Process

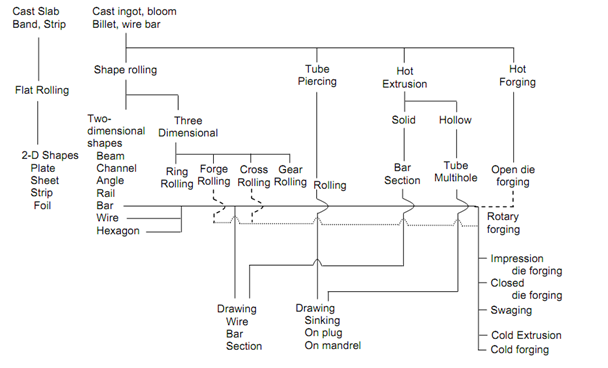

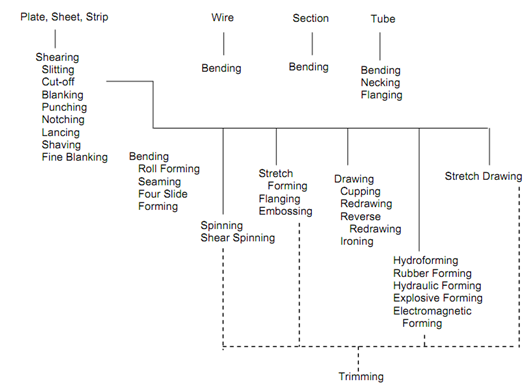

The starting material in bulk deformation processes is a slab, ingot, billet, and so forth, produced by casting into stationary molds or by continuous casting techniques (Figure 5). Primary deformation processes such as hot rolling, tube piercing, extrusion, open-die forging are then used for converting the cast structure. The product may be suitable for immediate application, but in many cases it serves as the starting material for another deformation process, such as drawing, hot and cold forging, sheet metalworking, etc. (Figure 6).

Figure 5 : General Classification of Bulk Deformation Processes

Figure 6: General Classification of Sheet Metal Working Processes