Bars of Uniform Strength

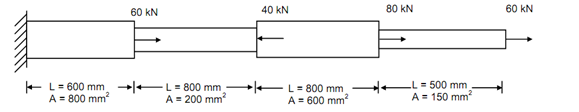

If we determine the stresses induced in the several segments of the bar illustrated in Figure, we obtain the following results:

σ1 = (160 × 1000)/800= 200 N/mm²

σ2 = (100 × 1000)/200= 500 N/mm²

σ3 = (140 × 1000)/600= 233.33 N/mm²

σ4 = (60 × 1000)/150 = 400 N/mm²

The results illustrate that the bar must be made of a material having permissible stress not less than 500 N/mm². Such a material (must be specially manufactured, if needed) is wasted in segments where the stress induced is much less. For example, in segment 1, the stress induced is just 200 N/mm². If we decrease the cross sectional area of segment 1, 3 and 4 to 320 mm², 280 mm² and 120 mm² respectively, the stress in all of the segments shall be uniformly 500 N/mm2, the bar would be safe & we would have considerably effected economy of material. Such a bar is known a bar of uniform strength. A designer shall strive to attain a bar of uniform strength, whenever possible. Though, because of other constraints & variations in loadings, it might not always be possible to provide a bar of uniform strength. Therefore, the concept of bar of uniform strength is a design ideal aiming to effect maximum saving in the material.