Universal Interface:

Coming back to CAD/CAM exchange, the heart of any CAD/CAM model is its component databases. That includes information of points, arcs, lines their relations and their locations. This data is made available for use in all of the succeeding applications as FEM analysis, solid modelling, procedure planning, CNC Programs generation, Material Requirement Planning (MRP), and inspection programs etc. Therefore we have to discuss a universal data exchange system for all of the applications of CAD/CAM data exchange.

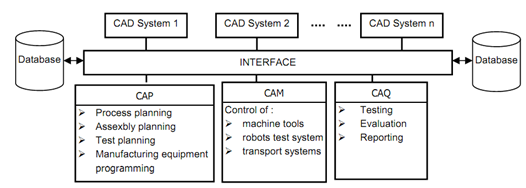

The concept of a universal data exchange system is illustrated in Figure. In this figure, this is shown how several CAD systems communicate along with the production planning and control system. The adaptation of protocols, data formats and data transmission rates are done by the interface. The interface should provide real time compatibility and it should ensure that the semantics of the exchanged information is maintained. Data conversion might be directly done in the interface with preprocessors or postprocessors. With the help of such an interface it becomes possible to utilize existing software and hardware modules for several applications in a factory. Additionally a company's own manufacturing data may be easily merged with those from vendors and suppliers. This is also possible to build manufacturing planning and control systems from heterogeneous modules supplied by different vendors.

Figure: Universal Interface for Interconnecting the Computer Planning and Control