Effects of Machining Variables on Surface Roughness:

Surface quality of a part may influence its service life. The surface quality includes characteristics as surface roughness, and surface defects. Surface roughness is a characteristic normally considered throughout design of a part. Surface roughness is based upon the spacing among the ridges and valleys particularly their widths , heights and direction (lay).

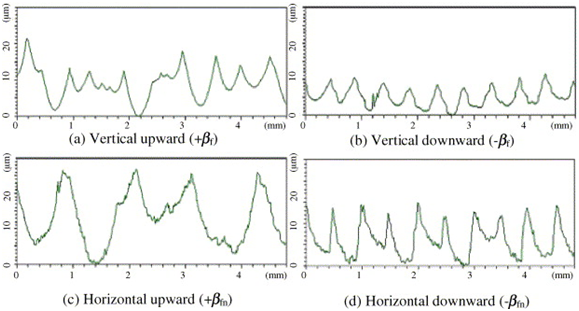

The theoretical value of surface roughness (peak-to-valley height) generated by a tool along zero nose radius (r = 0) is specified by following:

.-------------------------(10)

.-------------------------(10)

here, φe and φp are illustrated in the Fig 10 (Unit 7), f is feed per revolution. It might be illustrated that surface roughness value Rmax might be expressed in terms of its centerline average Rcla as following:

Rcla == Rmax/4 ------------ (11)

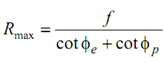

Figure: Surface Profile as Produced by Turning with a Sharp Cutting Tool (r = 0)

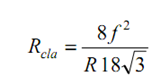

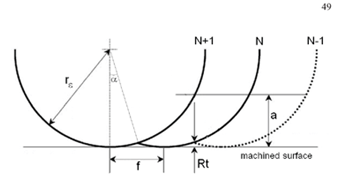

The theoretical surface roughness (Rcla) generated by a tool with finite nose radius (r > 0) (Figure 13) is specified by :

Figure Surface Profile as Produced by Turning with a Cutting Tool having a Finite Nose Radius (r > 0)