Cobalt and Nickel Based Superalloys

These alloys are also hardened either by strain hardening or precipitation. However, the difference between iron based and cobalt based alloys is that most of the iron is replaced by cobalt. The nickel based superalloys are most widely used for high temperature applications such as gas turbines. Those alloys are strengthened by precipitation of Ni3Al or Ni3Ti or their mixture. These precipitation particles are highly stable at high temperature because they make a large fraction of total volume of the material and are as large as 0.5 μ in diameter.

This size is very large as compared to the particles in low temperature precipitation systems. The presence of large particles does not permit other particles to form and grow and the existing particles may grow only at the expense of the neighbours which would then decrease in size. This process known as grain coarsening, is much slower than overaging process which particles in low temperature alloys grow in size. Ni and Co base alloys may be used in service upto temperature of 925oC.

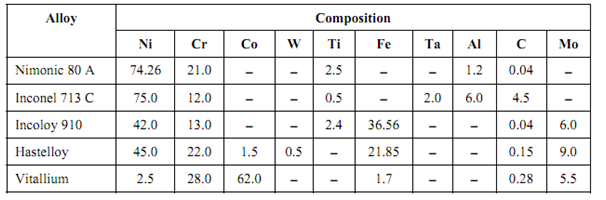

Table describes some alloys for high temperature applications.

Table: Composition of Some High Temperature Alloys