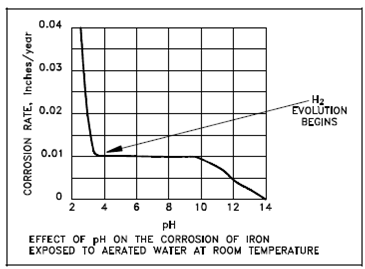

Effect of pH on the Corrosion Rate of Iron in Water:

Firstly, let consider the exposure of iron to aerated water at room temperature (aerated water will hold dissolved oxygen). A corrosion rate for iron as a function of pH is described in above figure. In the range of pH 4 to pH 10, the corrosion rate of iron is associative independent of the pH of the solution. Within this pH range, a corrosion rate is governed hugely through the rate at that oxygen reacts along with absorbed atomic hydrogen, by depolarizing the surface and permitting the reduction reaction to continue. Intended for pH values below 4.0, ferrous oxide (FeO) is soluble. Therefore, the oxide dissolves as it is created rather than depositing on the metal surface to form a film. Within the absence of the protective oxide film, the metal surface is in direct contact along with the acid solution, and the corrosion reaction proceeds at a greater rate than it does at higher pH values. It is also observed in which hydrogen is produced in acid solutions below a pH of 4, denoting in which the corrosion rate no longer depends overall on depolarization through oxygen, other than on a combination of the two factors (hydrogen evolution and depolarization). To pH values above about pH 10, the corrosion rate is observed to fall as pH is increased. This is believed to be because of an increase in the rate of the reaction of oxygen with Fe (OH) 2 (hydrated FeO) in the oxide layer to form the more protective Fe 2O 3 (note which this effect is not observed in deaerated water at high temperatures).

Figure: Effect of pH on the Corrosion Rate of Iron in Water

A plot of the associative corrosion rate for iron at several pH values in 590º F, oxygen-free water is presented as Figure. The curve describes in which the corrosion rate of iron in high temperature water is lower in the pH range of 7 to 12 than it is at either lower or higher pH values (at very high pH values, greater than pH 13.0, a oxide film becomes increasingly more soluble since of increased formation of soluble FeO2 at high temperatures, and corrosion rates increase). Conclude of the data plotted in Figure and other same measurements, it is common practice to manage high temperature water in the alkaline condition (but below extremely high pH values) to minimize a corrosion of iron and the steels exposed to the high temperature water.