Converter Construction:

Externally, a converter resembles a huge cylindrical tank resting on its side. Those are openings at every end for the essential piping connections. An outlet end of the converter holds the "A" and "B" stream procedure gas outlets. The other end holds the mixed process gas inlet and the level coolant inlet and outlet. The cylindrical tank is known as the shell and is constructed of steel along with welded joints. This internal surface is nickel plated. Those are three external reinforcing flanges around the outside of the shell. The several hundreds of barrier tubes, or tube bundles, hold within one converter are held in place through the spool or spool piece. A spool consists of struts and a central tube, or core that is perforated and permits categories of the "A" stream leaving the barrier tubes to find the converter outlet. In the either end of the core are tube sheets within the holes of that the barrier tubes are sealed through swagging or rolling. Tube sheets are also mounted on the core among the end tube sheets to support a barrier tubes.

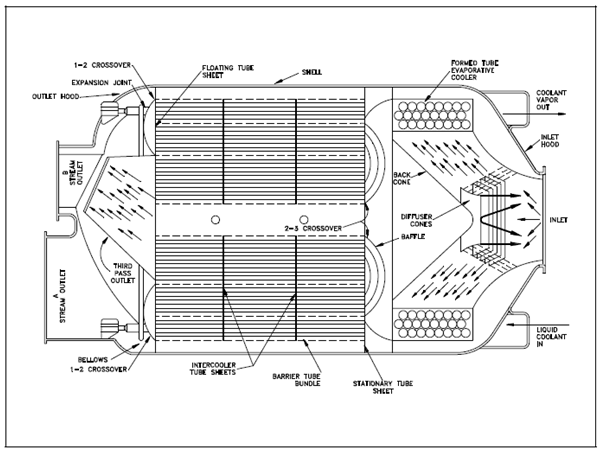

Figure: Typical Converter

The remainder of the converter equipment, along with the exception of the gas cooler, is designed to straight the procedure gas flow within the converter.