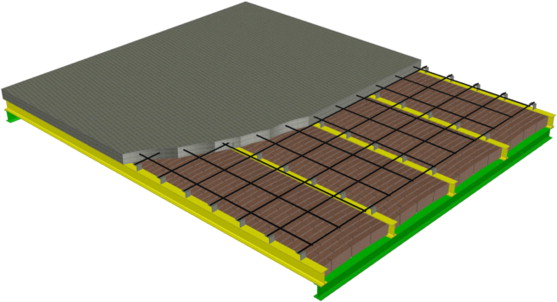

Brick Jack Arch Flooring

The construction on jack needs centering of 30 to 40 mm thick segmental piece of timber, along with chord length equivalent to the span of the arch and conforming to the soffit. After that centering board is cut slightly at the ends and is made to rest on the lower flange of RSJ, along with the curved surface upwards. Figure 6 displays the details of brick jack arch flooring. Instead, a bend iron strap is attached to its ends to form a hook by which the

(a) Jack Arch

(b) Centering Details

Figure : Brick Jack Arch Floor

centering board is suspended from RJS, as display in the Figure. After the centering is ready, bricks are laid on edge from both the joists. An end bricks are cut suitably to fit firmly along with the joists. Just well-burnt bricks are used for the construction, and they are saturated along with water, before use. Joists are encased in cement mortar, so as to avoid their rusting from lime mortar. The bricks are laid in like a way in which essential bond is developed among various rings or layers of bricks. In the first ring, the bricks are laid in lengths of 20 cm and 10 cm instead, to secure good bond among this ring and the next ring along the length of arch (perpendicular to the span). The key brick at the crown is laid in rich mortar, and is pushed as tight as possible. After the first ring is done, the centering board is advanced or pushed 20 cm additionally, through light blows of hammer, to construct the second ring. The second and successive rings are constructed using 20 cm long bricks. The last ring, however, is constructed along with alternate bricks of half and full lengths. The entire brickwork is watered or cured for 15 days. The top flooring is then given on a bedding of lime concrete or light weight cement concrete put on spandril.