Activation and Utilization of a Resource:

Activation and Utilization of a Resource are not Synonymous or the similar Thing

Usually, activation of resource and utilization of resource are treated as similar thing. Goldratt, in his TOC, treats these two issues separately. Initial, let us understand what the difference among utilization and activation is?

Activation

"What we must do" is activation. It is the indication of doing the needed work. Activation is directed towards effectiveness. It is system's measure of holistic approach or performance. A non-bottleneck machine can be active (producing 100%), yet not doing anything useful beyond the capacity of bottleneck.

Utilization

"What we may do" is utilization. This also includes performing work not needed at a specific time. Utilization is directed towards efficiency. This is a reductionist measure of performance or mechanistic approach.

Example

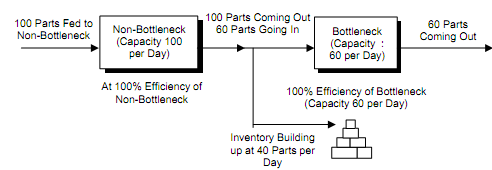

Figure: Both Non-bottleneck and Bottleneck Operating at 100% Efficiency

Let us suppose that a non-bottleneck has a capacity of 100 parts per day whereas a subsequent bottleneck has capacity of 60 parts per day .While both resources work at 100% efficiency, the inventory building-up is 100 - 60 or 40 parts per day. Thus, at a global or holistic level, the system (combined) is operating at just 60% efficiency level as throughput is 60 parts per day. Therefore, the utilization of non-bottleneck (that means. 100%) is not same as its activation (i.e., 60%) as this is effective for only 60% of its capacity.

Traditionally, utilization and activation have been considered as similar. TOC/OPT/Synchronous manufacturing treats these separately.

Thus, the scheduling of all non-bottleneck resources of the manufacturing systems must be done on the basis of the constraints of the system that means bottleneck resources). A non-bottleneck must be scheduled so that it is always available, when required, to support the bottleneck resource. However, it might not remain busy all the time.