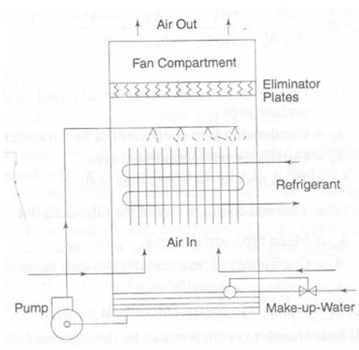

Evaporative Condenser:

These condensers contain some of features of both air-and water-cooled types. Air and water both are employed like a condensing medium. Water is pumped through the sump of the evaporative condenser to a spray header and then sprayed over the condenser coil. At the similar time a fan thaws air through the bottom-side of the condenser & discharges it out at the top of the condenser. An eliminator is available above the spray header to prevent particles of water from escaping along the discharge air. The spray water coming in contact along the condenser tube surface evaporates into the air stream. The resource of heat for the purpose of vaporizing the water is taken from the refrigerant, so condensing the gas.

The evaporative condenser joints the functions of the water-cooled condenser & the cooling tower and therefore occupies less space. Furthermore, it required less power than a water-cooled condenser. But the most of the troublesome point regarding the evaporative condenser is the complexity in keeping the surface of the condenser coil clean. The condenser coil being hot and wet both in operation, the dirt carried with the air stream produced a hard layer on the condenser. Scale also forms a solid layer if hard water is utilized. Once these hard layers are permitted to form, this is never possible to effectively clean the coil. Thereby the capacity of the condenser gets substantially affected. Due to this maintenance problem, evaporative condensers are not a lot in favour.

Evaporative Condenser