Precast Concrete Piles

These piles are commonly cast near the site of work in specially prepared casting yard along with adequate supervision and control to generate good quality concrete. The casting yard should be a leveled firm area along with proper drainage and located as close to the site as probable so that expenses on transporting are limited. The formwork of steel or timber should be of the needed specifications and should be properly cleaned and oiled before placing the reinforcement cage. As far as probable, longitudinal reinforcement should be in one length. In that case this is not probable, overlaps shall be staggered and preferably joints shall be butt welded. Essential stirrup shall be given and they shall be closely spaced near the top and bottom of the pile to prevent damage because of high impact stresses. The concreting of every pile has to be in one continuous operation and by compacted along with vibrator. The exposed face must be trowel finished to give a dense even surface. Side shuttering could be removed after a day and piles cured through wet gunny bags for a period of ten days. A piles should be carefully examined to see while there are any defects, previous to they are taken to site for driving.

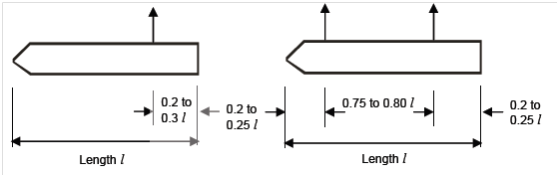

These piles are reinforced not just to carry the load on the foundation other than also to withstand the stresses generates in lifting the piles and carrying them to the place of installation. In precast concrete piles, commonly the reinforcement needed withstanding the stresses during handling and driving are more than in which needed to take the load on the foundation. Piles could be lifted through hooks or clamps at a single point or at two points (Figure 16). Hooks could be embedded at the time of casting or proper markings made so in which slinging is done correctly.

The reinforcement has to be correctly designed according to the proposed mode of lifting. The high stresses generates although driving and lifting, necessitates proper structural design of the pile to take the bending and shear stresses. At once the pile is driven within the ground; much of the steel becomes redundant as the stresses are majorly compressive. Piles could also be manufactured within a factory but transportation of long piles to the site could pose problems.

Figure : Lifting of Precast Piles

If it has been decided to adopt precast piles for the foundation, the length of piles has to be assessed fairly properly, as cutting the piles or extending them cannot be complete easily. They also needed large casting yards and heavy equipment for driving and handling.

Thus, in situations whereas soil is such in which driving is simple or large number of piles of predetermined length is to be given or where reinforcement is needed from considerations of lateral pressure or tensile steel is needed to resist uplift, precast piles are beneficial. The excellence of concrete in precast piles is better as they are cast above ground under controlled conditions and thus, such piles are sometimes preferred within aggressive soil (e.g. sulphates) conditions.

Precast concrete piles for little loads and short lengths could be square in cross-section along with chamfered corners, although for longer length and heavier loads they are commonly of octagonal or circular section. Sometimes hollow sections are also used that are filled along with concrete after driving. The advices are pointed to facilitate driving. As the reinforcement within the pile is mainly to resist the handling stresses, this objective could also be achieved through prestressing. It could be either pre- tensioned or post-tensioned. Prestressed concrete piles are not hugely used as they are rather expensive.