Flexible Manufacturing System

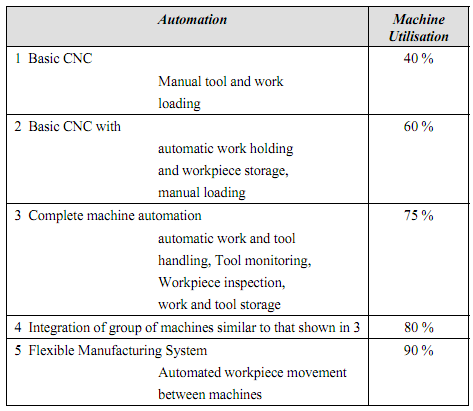

It is a known fact that the use of CNC machine tools provides flexibility in terms of the low job changing time. However the full potential of automation cannot be achieved simply by the use of the CNC machine tool alone. Manufacturing a part involves not only the machine tool, but also the other associated facilities such as blank material, tooling and manufacturing instructions at the right time. The net result is that the effective CNC machine utilisation can only be achieved if all of the associated requirements for manufacture are integrated in some manner with the machine tool. Some typical figures for machine utilisation based on general trend in the industries is given in Table 1.

Table 1 : Automation Benefits

Typical extremes in manufacturing systems are the job shop type systems, which can produce a large variety of parts but at a high cost compared to the transfer lines that can produce large volumes of products at economical cost. In between these two extremes lie a variety of manufacturing systems based on CNC machine tools that reduce the flexibility without sacrificing the economy. They need varying degrees of integration to achieve the right amount of flexibility and economy. Collectively all these type of systems can be termed as flexible manufacturing systems.