Screw Compressor:

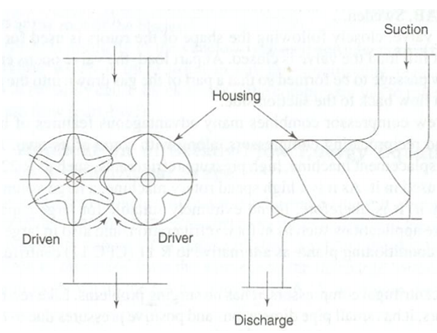

Rotary screw compressors also relate to the category of positive displacement compressors machine a rotary compressor basically consists of two helically- grooved rotors as shown in given fig that rotate in housing.

The male rotor contains lobes and normally it is the driving rotor. The female rotor contains gullies and normally it is the driven rotor. A four-lobe male rotor shall drive a six-gully female rotor at two-thirds of its speed. At 3600 rpm the several compressed gas discharges of a four-lobe rotor shall be 4 * 3600 = 14,400 per minute.

Sectional and Side Views of a Screw Compressor

Since in the case of other positive displacement machines, there are three fundamental continuous phases of the working cycle, like compression, suction and discharge. While the male rotor turns clockwise, an interlobe space among a pair & housing nearest to the suction ending opens and is filled up with the gas. There are four such kinds of pairs to be filled up throughout one revolution in a four-lobe rotor & the suction periods overlap one another.

While remeshing starts, the volume reduces and the pressure rises. The charge is moved helically & compressed till the trapped volume attains the discharge end. Thus the compression ratio is fixed.

Furthermore rotation simply empty the rotors of the high pressure gas till the last traces of the gas are squeezed, irrespective of the pressure in the condenser.

On finishing point of the discharge phase, there is no residual gas enduring in the rotors. As a consequence, there is no expansion of clearance gases. The compressor contains no suction & discharge valves.

There are leakage paths in a screw compressor mostly across the line of mesh among the rotors & across the clearance among the rotors & the housing.

To remove leakage, oil is injected in a several small jets directed towards the mesh. Oil injection also serves the intention of cooling & lubricating along with that of sealing the leakage paths.

A slide valve, closely adopting the shape of the rotors is utilized for capacity control. At complete load the valve is closed. At part of the load, the valve opens enabling a return flow passage to be produced so that a part of the gas drawn into the interlobe spaces may flow back to the suction side.

The screw compressor combine various advantageous features of centrifugal and compressors both, along with some its own. Since it is a positive displacement machine, high pressure refrigerants, such like R-22 and ammonia are utilized in it. Since it is a high speed rotary machine, a great volume may be handled by it. Therefore, it is found tremendously suit able for large capacity low temperature applications such like in food refrigeration.

As reciprocating compressors, it contains no surging problems. It contains small pipe dimensions & positive pressures because of the utilization of high pressure refrigerants. As centrifugal compressors, it contains high compression efficiency, unloaded starting constant capacity control and no balancing problems. Also, the compressor is appropriate for large capacity installations.