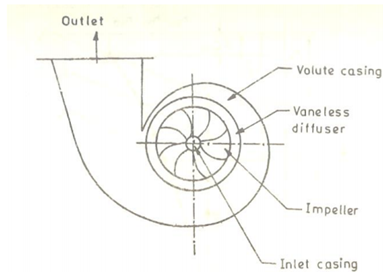

Centrifugal Compressor:

A single-stage centrifugal compressor primarily consists of the four components as shown in given fig.

(1) An inlet casing to accelerate the fluid to the impeller inlet.

(2) An impeller to shift energy to the fluid in the form of raise in static pressure & kinetic energy.

(3) A diffuser to translate the kinetic energy at the impeller outlet into pressure energy (static enthalpy).

(4) A volute casing to gather the fluid and to further translate the kinetic energy into pressure energy (static enthalpy).

In addition of these, there are intercoolers, in general integrated with the casing, in a multistage compressor. Usually the casing is made of cast iron & the impeller, of alloy (chrome-nickel) steels. The highest stress is developed at the root of the blades.

Normally the diffuser is vaneless type as it allows more efficient part load operation that is quite usual in any air-conditioning plant. A vaned diffuser shall surely cause shock losses if the compressor is run at compact capacity and flow.

Elements of a Centrifugal Compressor