Compressive Loading: Buckling:

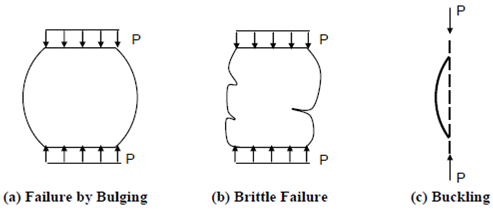

The behaviour of a member under compressive load is more complicated than under tensile loads. If a column is short, that is, its lateral dimensions are not very small compared to its length, it might fail through reaching its ultimate compressive strength (yield stress) and the failure may end up in bulging of the section or its cracking up depending upon the material of the column (Figures (a) and (b)). However, if a column is long, that is its lateral dimensions are small compared to its length, it bends or buckles (deflects from its initial straight position) at a load smaller than that causing pure compressive failure (Figure).

Figure

The phenomenon is elaborated in the subject of Strength of Materials where it is shown how the 'buckling' may be in three different equilibrium as defined below.

Stable Equilibrium

The components come back to its original position when the load is removed.

Neutral Equilibrium

It remains within the deflected position as such.

Unstable Equilibrium

The deflection goes on rising indefinitely causing ultimate collapse.

An ultimate compressive load depends upon:

- The material of the column that is expressed in terms of modulus of elasticity (E) and yield stress (σy).

- The effectual length of the column (le) that depends upon its end conditions (whether it is pinned, fixed or free).

- That's cross sectional shape and dimensions which gives its area (A), moment of inertia (I), and radius of gyration.