Effectual length of the lacing bars:

The effectual length of the lacing bars are calculated as follows:

(i) For single lacing along with riveted connection, it is the length between the inner end rivets.

(ii) For double lacings (effectively riveted at their intersections), that is 0.7 times this length.

(iii) For welded construction, it is 0.7 times the distance between the inner ends of the connecting welds.

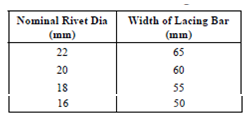

- Width of lacing bars depends upon the nominal rivet diameter as given in Table 4 below.

Table: Width of Lacing Bars

- A thickness of lacing bars shall not be less than the following:

(i) l/40 for single riveted lacing;

(ii) l/60 for double riveted lacing;

(iii) l /60 for welded lacing;

while l is the length between inner end rivet/welds.

- Angle of Inclinations: Whether within single system or double system the lacing bars shall be inclined neither less than 40o nor more 70o to the axis of the member.

- Spacing: The maximum spacing of the lacing bars (while riveted or welded) shall be such that the minimum slenderness ratio, λ′ = l ′/ r ′ of the components of the column between connections is not greater than either 50 or 0.7 λ (where λ is the most unfavourable slenderness ratio of the member as a whole), whichever is less.

- Attachment to Main Members: The riveted or welded connection of the lacing bars to the main members shall have sufficient strength so as to transmit the load in the bars. While welded lacing bars overlap the members, the amount of lap measured along either edge of the lacing bars shall not be less than 4t (where t is the thickness of the bar or member, whichever is less). Welding shall be provided along each side of the bar for the full length of the lap. Welds are to be fillet welds or full penetration butt welds.