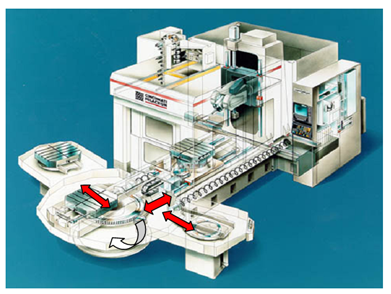

Horizontal Axis Machining Centre

A distinctive CNC machining centre equipped along ATC and APC are illustrated in Figure 16.The pallet changer shown in Figure 16 consists of 4 pallet locations with three pallets. One pallet location is near the spindle where the actual machining takes place, while two locations B and C are meant for work piece setup, loading and unloading. The fourth location at the center is that used for exchange with the pallet near spindle after completing the machining operation by simply indexing. While the machining of the component on the pallet near the spindle is done, that pallet moves into the central indexing location, where the pallet with the next part is already in position. Then the shuttle mechanism allows the pallet to be indexed to allow the pallet with the blank to move to the spindle to carry out the machining operation. Since the machine tool starts machining the pallet shuttle shall do the necessary pallet transfers to the empty position for unloading.

Figure 16: High Production Horizontal Axis CNC Machining Centre with Automatic Tool Changer and Automatic Pallet Changer

The machine shown in Figure 16 has only a small number of pallets in position which is not conducive for long unattended operation. This is also possible to integrate such a machine with a separate pallet carousals that can be linear or rotary with larger number of pallets for long hours of unattended operation of the machines. Such systems are normally used with machining systems that may be integrated with more number of machine tools into an integrated operation.

The vertical axis machining centre is one of the most commonly used machine in the machining of dies and moulds in the tooling industry. This is generally provided with a variety of accessories to cater to a larger spectrum of jobs that can be completed by them in a single setup. Most of these come with 3 axes. Additional axes might be added, for example the spindle head can be swivelled in one or two axes (around X or Y axis) to provide A or B axis motion .These are required for more complex machining of 3D surfaces as are commonly employed in dies and moulds, & the aerospace industry.

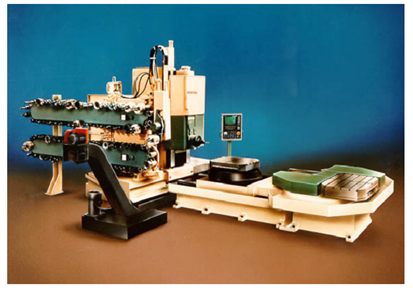

A horizontal axis machining centre or popularly called as HMC (Figure 17) is heavier than the vertical configuration and is normally used for large metal removal rates. Rotary table is one of the most common accessories used with the horizontal machining centre. This provides a fourth axis in the form of B. The availability of any rotary table in horizontal machining centre makes it possible for the machining of all four faces of the component that are facing the tool. Therefore a large part of the component might be finished in a single setup allowing for closer tolerances for the critical components.

Figure 17: A Typical Horizontal Machining Centre with an Automatic Pallet Changer

The rotary tables can also have some swiveling ability. For instance the rotary table can have two rotary motions in A and B axes in place of the conventional C-axis. If such type of rotary table is interfaced with a conventional 3 axes horizontal machining centre (or a VMC) then it will be possible to machine complex sculptured surfaces.