Work Holding Devices

Work holding in CNC machine tools is more significant since the conventional work holding devices such as vices or chucks are rarely used except for very simple components. For complex shapes of the work pieces it becomes necessary to use some special fixtures for quick setup of the work pieces. The modular fixturing systems, which are in vogue for conventional machine tools have been refined and are widely used for holding the work pieces in CNC machine tools.

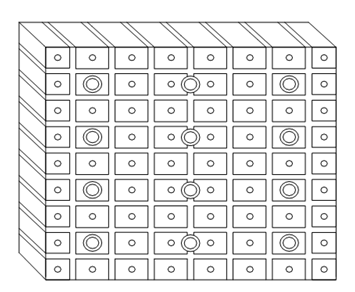

Grid plates are generally used as one of the fixturing bases. The grid plates are provided with precisely drilled and tapped holes to facilitate the clamping operation as shown in Figure 7. Since the holes on these grid plates are made at precise positions, the operator would know the exact location of the component depending upon where he is clamping. These grid plates can be permanently clamped on the machine tool table if necessary. This can be very conveniently used together with the zero shift facility (G53 to 58) to clamp even multiple small components.

Figure 7: A Grid Plate with Holes which can be used as a Machine Table

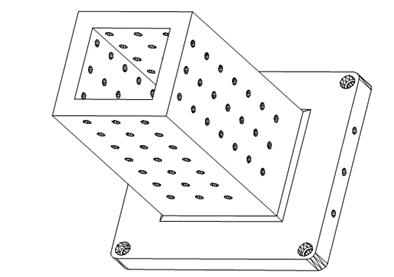

The grid plate can also come in the form of a cube with 4 parallel faces which can all be used for clamping multiple work pieces as shown in Figure 8. This fixture in conjunction with a rotary table will allow it to be used as an indexing fixture for clamping more work pieces to the machine tool in a single fixture.

Figure 8: A Tombstone for Mounting Multiple Components on Different Faces

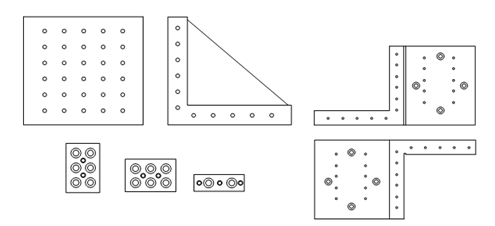

In addition to these standard fixture bases, a big number of fixture elements such as angle blocks and base elements (Figure 9) are used to quickly clamp the work pieces in position.

Figure 9 : Modular Fixture Elements used for Supporting Complex Work pieces