In-Process Gauging

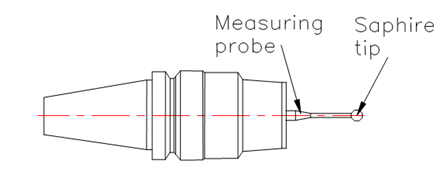

The measurement of dimensions during the machining operation helps to keep the machining operation in a close check. For this reason the touch trigger probe is normally used. The touch trigger probe consists of a sapphire sphere joined to a rigid measuring unit as shown in Figure 21. The measuring unit is mounted in an adopter and clamped in the spindle similar to the normal tools. The measuring units have an omni-directional switch that will be triggered whenever the measuring unit experiences a small elastic deflection. This switch will be used to arrest the motion of the axes.

Figure 21: Touch Trigger Probe Used for Inspection on a CNC Machine Tool

For the purpose of measurement, the probe will be commanded with a motion away from the surface, which needs to be measured. As the probe approaches the surface it will slow down and will completely stop when it touches the surface. There will be a small elastic deflection of the measuring unit when it touches the surface, but the controller will be able to compensate for the deflection. The present position of the probe tip in terms of the x, y and z coordinates are recorded. Likewise the probe can touch different points on the surface, whose coordinates can be recorded. Then based upon the geometry of the different points, it would be probable to compute the dimensions or any other tolerance parameters. Some examples are given later for clarification.