CNC Machining Centres

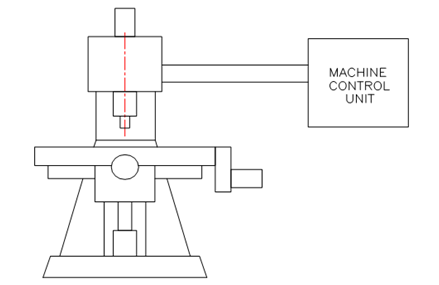

As noted earlier, the first CNC machine developed was a vertical axis milling machine retrofitted with the control by changing the appropriate elements in the process. The initial developments in the machine tool industry continued this trend in the initial stages to convert the popular machine tools by making the necessary changes in the controlling part only. However, this trend has been changed in the later years after recognizing the full potential of CNC machine tools. Therefore special CNC machine tool designs have been done to take greater advantage of the controlling capability.

Figure 14: A Typical Vertical Axis Milling Machine Retrofitted with a CNC Controller

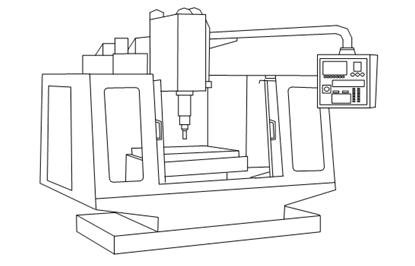

The CNC milling machines have been successfully improved with a variety of options to improve the productivity and flexibility. As a consequence now these are called as machining centres to reflect that versatility, and this is possible to do all the milling and hole making operations to the highest possible accuracy thereby reducing the other finishing operations. A typical CNC machining centre is shown in Figure 14. The CNC machining centres can be broadly categorised into two varieties:

- Vertical axis machining centre, and

- Horizontal axis machining centre.

Figure 15: Present Day Production Vertical Axis CNC Machining Centre

In addition to the basic improvement in a number of machine tool elements that contributed to the productivity, a number of necessary attachments have been developed to increase the machine utilization rate. One of the significant options is the automatic tool changer or ATC as is generally called, is utilized for changing the cutting tool in the spindle in the shortest possible time of the order of 3 to 6 seconds. The details are given in Unit2.

Another such important option is the automatic pallet changer or APC for changing the work piece on the table in the shortest possible time, typically of the order of 10 seconds. Generally the components machined on machining centres require large cycle times. Many a times they also require large setup times. Therefore it would be preferable to setup the work pieces away from the machine tool such that the machine utilisation is improved. For this purpose pallet, which is a smaller version of a machine tool table is used with the machining centre. Normally these are available in standard sizes with precision drilled holes or with T-slots like a machine tool table. The blanks can be clamped, setup and unclamped on these pallets at a location away from the machine spindle thus, not disturbing the machining function.