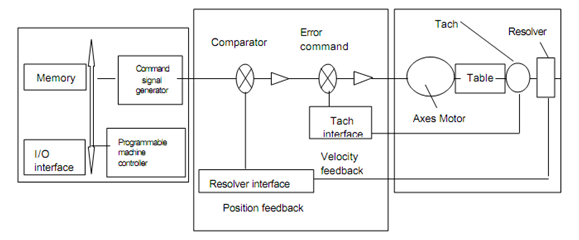

Closed Loop CNC Drive System

With closed loop drive systems, feedback subsystems are utilized to monitor the actual output and accurate any discrepancy among the desired and the actual system performance. Feedback s ubsystems are of two kinds:

Analog Feedback System

Variations in physical systems such like position & velocity are being measured as voltage levels in analog feedback system. Tachometers are typically utilized to measure the velocity, while the resolvers are utilized to measure position. In CNC drive systems there are two feedback loops; position loop and velocity loop as illustrated in Figure. The position loop is the outer loop that consists of comparator, a velocity loop, an amplifier circuit, a resolver, and a resolver interface.

Digital Feedback System

A digital feedback system utilizes a digital position transducer to measure the position. Encoders are well known digital position transducers. Comparator & amplifier are replaced by up-down counter & digital-to-analog converter.

Analog Closed Loop CNC Drive