Classification of CNC System

The motion of the tool in a NC machine tool is basically in two modes:

1. Point to point, and

2. Continuous path

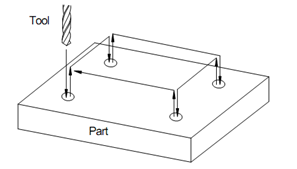

The point to point systems make the tool to move from one point to the other in rapid motion, while performing a certain operation at each of these points as shown in Figure 1. This is generally used for drilling and punching operations. The controllers are relatively simple and low cost for such operations. The type of applications can be PCB drilling machines or sheet metal punching presses. The motion path taken between the points is generally at the fastest speed possible, thereby reducing the idle time.

Figure 1 : Point to Point Tool Movement

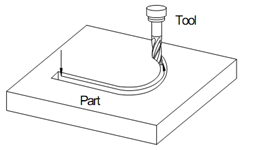

In the case of continuous path movement, the tool will move in any of a number of valid axes simultaneously through a specified path such as a straight line or circular as shown in Figure 2. This calls for an interpolation to be worked out by the controller for all the intermediate points so that the tool will be able to trace the path properly. The capability of the contouring machines is such that they may have simultaneous interpolation from 2 to 5 axes depending upon the profile geometry being generated. These controllers are generally expensive because of the larger capability of the computers involved.

Figure 2: Continuous Path Tool Movement