Washing Process ofRapid Gravity Filters:

The supporting gravel beds are omitted if porous plate filter bottoms are provided. When gravel bed is provided, it should have a thickness of around 45 cm, making total thickness of the filter media around 1 m. The gravels should have size between 2 mm and 60 mm. The basic requirement for the filter bed is that it should consist of a large number of orifices, uniformly arranged to collect filtrate and deliver air and wash water to the filter bed. At the same time, they should preclude the passage of the filter media.

The filter has four valves to control inlet, outlet, wash water and the drain to waste. For air to be used with wash water, a fifth valve on the air pipe is provided.

Each filter has an area around 100 m2 and depending upon amount of water to be filtered number of such units may be evaluated and installed.

The depth of water above a filter bed is kept around 2 m. The flow of water through sand is streamlined and the loss of head is proportional to the velocity.

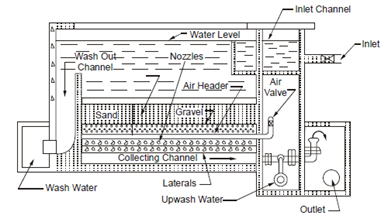

Typical sketch of Rapid Gravity Filter is shown in Figure.

Figure: Rapid Gravity Filter

For cleaning, the inlet and outlet valves are closed. The drain valve is opened to lower the level of water to the level of the weir wall that holds the sand bed in position. The air scour is operated for about 3 minutes. This operation forces air upwards through the sand at a rate of about 1 - 1.5 m/min/m2 under a pressure of 0.42 kg/cm2. When water over the bed gets thoroughly agitated, up wash water is turned on at a rate of about 0.5 m3 /min/m2 and allowed to run until the clean sand bed can be seen. Generally, in practice, it takes about 5 minutes during which time the wash water get falling over the cross-wall weir and escapes through the open drain valve. In some filters, air scour and water scour are applied simultaneously. When the filter gets washed the drain, upwash and air valves are closed and the inlet valve opened to recharge the filter. Normal service is returned by opening the outlet valve slowly to give the filter bed time to settle down and rid itself of any loose sediment stirred up during the washing process.