Upper Floors

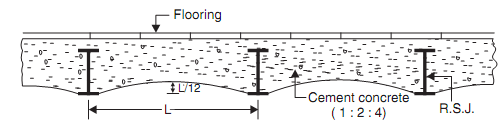

In olden days upper floors were made of or steel joist or timber floors and stone slabs. Jack arch floorings were used for larger spans. Jack arch floor consisted of I-section steel beams supported on gap and walls between I-sections beams filled with concrete arch. Given figure shows a typical jack arch flooring.

Jack arch flooring

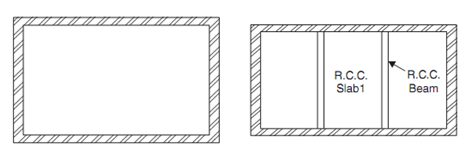

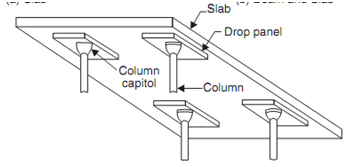

At the present time R.C.C. floors are used commonly. It may consist of slab only, if span is less or it may be beam and slab flooring. Many provide flat slabs in halls of hotels and assembly, For instance directly slabs supported over columns. Columns are provided with widened portion called column head. They give graceful look to halls, mostly when the head room is high. R.C.C. floors need correct thickness and reinforcements. By structural design engineers they are arrived at. Given figure shows R.C.C. slabs.

(a) Slab (b) Beam and Slab

(c) Flat slab

R.C.C. floors

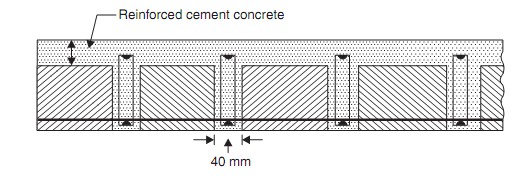

Concrete is used to resist compression and steel to resist tension in R.C.C.. Therefore the concrete in tension zone do not contribute in resisting the load. It keeps the steel only at required position. In reinforced brick slab to replace concrete an attempt is made in tension zone by bricks. This is better thermal efficient than solid concrete floors. Given figure shows a typical reinforced brick slab.

Reinforced brick slab

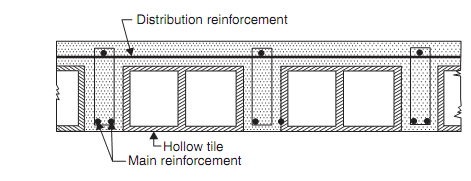

In hollow or ribbed tiled flooring, in tension the concrete portion is replaced by hollow tiles. Given figure shows a typical floor of this type.

Ribbed or Hollow tiled flooring

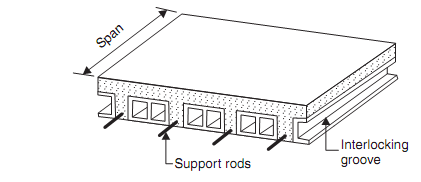

In precast concrete floor panels can be used which helps in avoiding form, storing of sand, works ,coarse aggregates etc. at the site and also curing. In the structure factories manufacture these units which are to be placed over supports. Given figure shows the cross-section of a typical precast floor unit. These units are available in the 0.25 m widths and in several spans. Interlocking grooves are provided with adjoining units on the sides to get tight connection.

Precast floor unit