Properties of Hardened Concrete

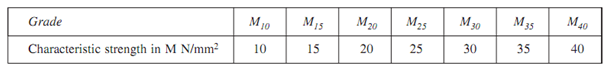

1. Strength: After 28 days of curing the characteristic strength of concrete is defined as the compressive strength of 150 mm size cubes below which not more than 5 %of the test results are expected to fail. Unit of stress used is N/mm2. IS 456 grades the concrete based on its characteristic strength as shown in given table

Grades of concrete

Till the year 2000, M15 concrete was allowed to be used for reinforced concrete works. But for reinforced concrete works ,IS456-2000 specifies minimum grade of M20 to be used.

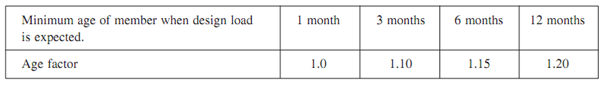

Strength of concrete depends upon the amount of cement content, grading of aggregates and quality, water cement ratio, curing and compaction. In the initial stages Strength of concrete is gained. The strength gained is as much as 60% to 65 %of 28 days strength In 7 days. It is customary to suppose the 28 days strength as the complete strength of concrete. But after 28 days concrete gains strength also. The characteristic strength may be increased by the as factor given in given table

Effect of age factor on strength of concrete

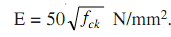

From the formula ft = 0.7 fck N/mm2, the tensile strength can be estimated, where fck is stand for characteristic compressive stress. The modulus of elasticity can be estimated from the given formula:

2. Dimensional Change: with age Concrete shrinks. The total shrinkage depends upon the size of the member, constituents of concrete, and the environmental conditions. Total shrinkage is about 0.0003 of original dimension.

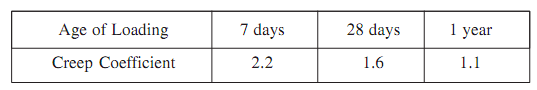

Due to loading over a long period the permanent dimension change is termed as creep .in concrete Its value depends upon the stress , at the time of loading and the duration of the loading the age of the concrete. From the values of creep coefficient the ultimate creep strain can be estimated. The creep coefficient is described as ultimate creep strain at the age of loading divided by the elastic strain. These values are listed in following table

Creep coefficient based on the age of loading

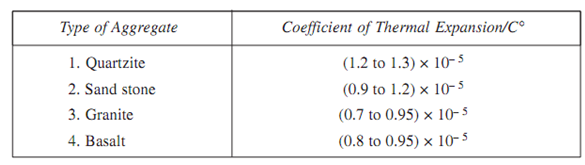

Due to thermal expansion Size of concrete may change also. The coefficient of thermal expansion depends upon the nature of cement, cement content, the type of aggregates, relative humidity and the size of the sections of the structural elements. Following table shows the coefficient of thermal expansion of concrete along with different types of aggregates.

Coefficient of thermal expansion

3. Durability: Environmental forces like, chemical attack, weathering, heat, and thawing and freezing attempt to destroy concrete. The period of existence of concrete is known as durability without getting adversely affected by these forces. In general strong and dense concretes have better durability. The cube crushing strength is not alone a reliable guide to the durability. Concrete should have sufficient cement content and should contain low water cement ratio.

4. Impermeability: Through its pores it is the resistance of concrete to the flow of water. During concreting Excess water leaves a large number of continuous pores leading to the permeability. Permeability should be kept very low Since It reduces the durability of concrete, using low water cement ratio, well graded aggregates and dense, good compaction and continuous curing at low temperature conditions. The cement content which is used should be enough to provide sufficient workability with low water cement ratio and the available compaction method.