LINTELS

Lintel which is a horizontal flexural member is spans over the openings in the walls for, windows, doors, ventilators, cupboards etc. by flexural action of the lintel, Load of masonry above the opening is transferred to the wall so that frames of doors, windows etc are not unduly loaded. For the lintel the end bearings should be at least 200 mm. The width of lintels is same as that of wall.

Lintels of different materials are used. They are following:

(1) Wood

(2) Stone

(3) Brick

(4) R.C.C. and

(5) Steel.

(a) Wood Lintel: Wood Lintel may be a single piece or may be assembled by joining 2 to 3 pieces. Sometimes by steel plates at top and bottom the wooden lintels are strengthened. Such type of lintels is called as flitched beams.

(b) Stone Lintels: Wherever stones are available stone beams are used as lintels. As in tension stone is weak they can be only used for small spans. Their depth is kept approximate 1/10 th span. Before using as lintels Stones are cut to the width of wall and dressed.

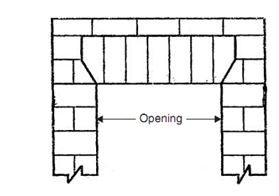

(c) Brick Lintels: Well burnt, good quality lintels are laid on ends or edges to form lintels as shown in given figure. At the time of construction it needs temporary form work. Before form work is removed the lintel is to be cured for 7-14 days. Such type lintels are useful to span small openings.

Brick lintel

(d) R.C.C. Lintels: In the building it is possible to provide R.C.C. lintels of any span required. They may be isolated or continuous over the openings. In the opening they are provided with suitable reinforcement-main reinforcements beings on lower side. Nowadays these lintels are used very commonly in buildings.

(e) Steel Lintels: Steel angles or rolled steel I-sections are used as lintels. To maintain the spacing between the sections Tube separators can be provided. Regular painting is necessary if the sections are opened to atmospheric action. Many times they are encased in concrete to avoid maintenance problem. For large openings these lintels can be used.