Piles Classification

According to the materials used Pile foundations are classified and also on the nature of load transfer.

According to Materials Used it can Classified as:

Piles may be classified as:

1. Timber piles

2. Concrete piles

3. Steel piles and

4. Composite piles.

(1) Timber piles: Circular seasoned wood may be used as piles. Their diameter can vary in the range 200 mm to 400 mm. likewise square piles of sizes 200 mm to 400 mm are also utilized. The length of timber pile might not be more than 20 times its lateral dimension. Bottom of the pile is sharpened and provided with iron shoe, so that by hammering it may be driven in the ground easily. These piles should be always kept below water table; or else alternating wet and dry condition cause the decay. These piles are cheap and can drive rapidly by hammering. Main disadvantage is their load carrying capacity is low and during driving it is likely to be damaged in the soil.

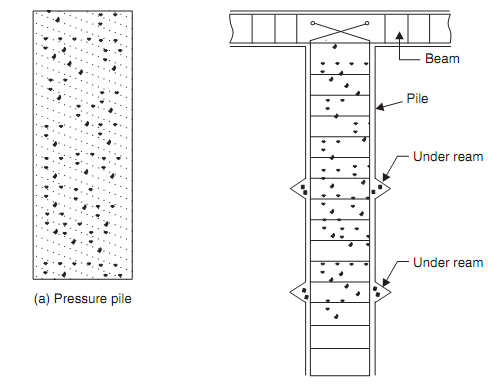

(b) Concrete piles: These piles can be further classified as precast piles and cast in situ piles. With steel Precast piles are reinforced and are manufactured in factories. Cross-section diameter/dimension varies in the range 200 mm to 500 mm. Circular, Square & octagonal sections are normally used. The length of piles can be up to 20 m. with steel shoe they are provided at the lowest end. These piles can fairly carry large loads. These piles are extremely resistant to biological and chemical actions of the soil. Disadvantage of these piles is they need more time to manufacture and heavy to handle. Given figure show concrete piles.

(b) Under-reamed pile

Cast in situ concrete piles

By boring the holes Cast in situ concrete piles are formed first in the soil and then concreting them. Usually Concreting is made by using casing tubes. If the hole is filled with plain only concrete it is pressure pile. By providing enlarged base Load carrying capacity of the piles can be increased.

In the bored holes the reinforcement caging can be inserted and to increase load carrying capacity one or two under reams can be formed. Concreting may be carried out after that. Such piles are known as under reamed piles. At regular interval of 2 to 4 m these piles are provided and capping beam is provided over them.

(c) Steel Piles: in the form of box a steel pile can be rolled steel I sections, tubes or fabricated. Mostly These piles are used as bearing piles since surface available for friction is less and also the coefficient of friction is less. If tubes are used by compressed air the soil inside the tube is driven out and concrete is filled. For driving close to existing structures these piles are very useful since they disturb the soil least.

(d) Composite Piles: Composite piles may be of timber and concrete or of concrete and steel. Wooden piles might not be subjected to alternating wet and dry conditions. Therefore they are preferred for the portion below water table. In situ concrete piles the portion above water table is built with cast.

If the required length of steel piles is less than the depth of pile, several times with concrete upper portions are built. Thus steel and concrete composite piles are sometimes used.

According to Load Transfer classification of Piles:

Piles may be classified as following according to the load transfer to the soil:

1. Bearing piles and

2. Friction piles.

By bearing, Bearing piles rest on hard strata and transfer the load. Such piles are preferred. These piles are used if the hard strata are available at reasonable depth.

By the friction, Friction piles transfer the load to the soil between soil and the pile. Such type of piles is used if hard strata are not available to a considerable depth. The friction developed is to be correctly assessed before deciding the length of the pile. Surface of such piles is made rough to increase the skin friction so that required length of pile is reduced.