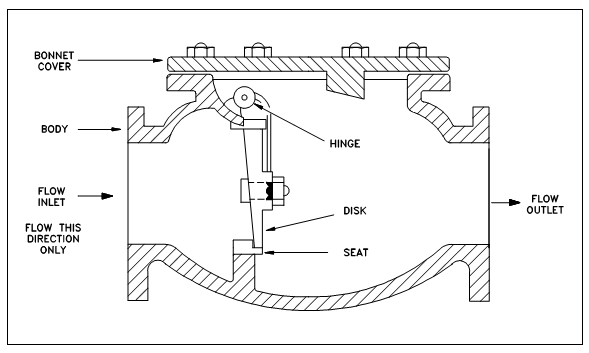

Swing Check Valves:

A swing check valve is described in Figure. The valve permits full, unobstructed flow and automatically closes as pressure reduces. These valves are fully closed while the flow reaches zero and avoid back flow. Turbulence and pressure drop inside the valve are extremely low.

Figure: Swing Check Valve

A swing check valve is generally recommended for use in systems employing gate valves since of the low pressure drop across the valve. These are available within either Y-pattern or straight body design. A straight check valve is described in above Figure. In other style, the hinge and disk are suspended from the body through means of a hinge pin. A Seating is either metal-tometal or metal seat to composition disk. Composition disks are commonly recommended for services whereas dirt or other particles might be present in the fluid, whereas noise is objectionable, or where positive shutoff is needed.

Straight body swing check valves hold a disk that is hinged at the top. The disk seals against the seat that is integral along with the body. This category of check valve commonly has replaceable seat rings. A seating surface is placed at a slight angle to allow simpler opening at lower pressures, more positive sealing, and less shock while closing under higher pressures.

Swing check valves are commonly installed in conjunction along with gate valves since they give relatively free flow. Those are recommended for lines having low velocity flow and should not be used on lines with pulsating flow while the continual flapping or pounding would be destructive to the seating components. This condition could be partially right through using an external weight and lever.